Posted to News on 11th Feb 2021, 09:15

Network integration – search for value and simplicity

Getting the balance right when implementing an Industry 4.0 ready network

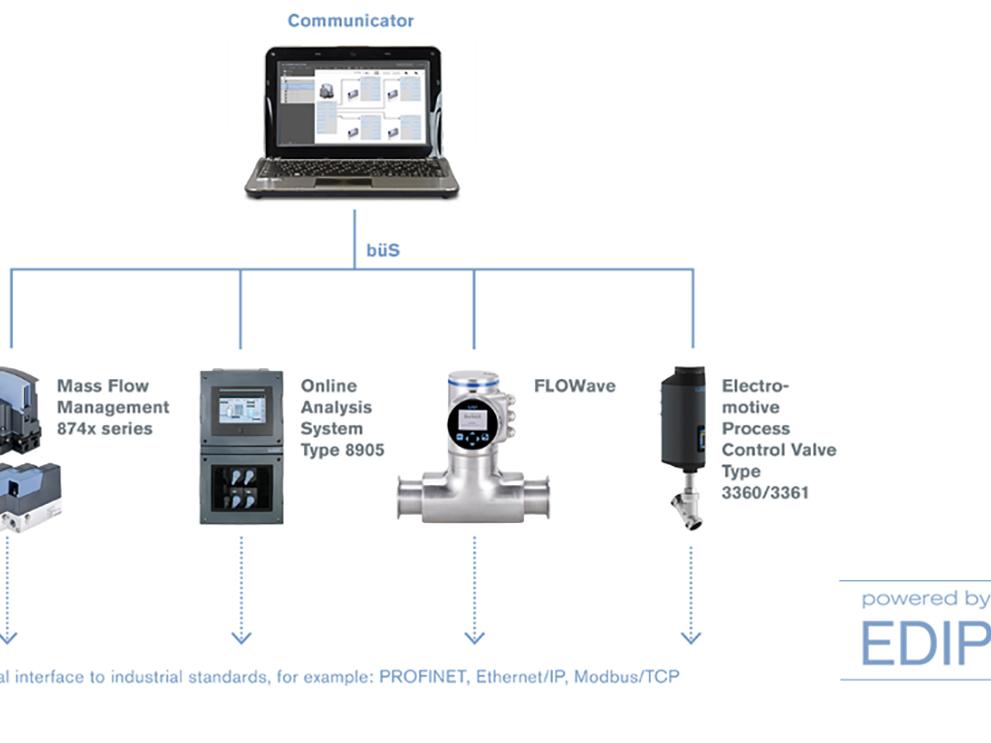

Bürkert, manufacturer of measurement and control systems for liquids and gases, is offering integrators the opportunity to achieve both cost-effectiveness and functionality with its Efficient Device Integration Platform (EDIP).

The platform, says the company, takes advantage of CANopen to reduce reliance on expensive manufacturer hardware, and standardise the monitoring and control of Bürkert valves, flowmeters and controllers.

Breaking reliance on chipsets

While system integrators have a wide selection of data communication protocols to choose from when implementing an Industry 4.0 network, once a protocol is chosen customers are usually locked in to using corresponding manufacturer’s hardware to ensure effective communication. This usually takes the form of chipsets, which will not only be required for the PLC, but for individual devices to communicate on the network too.

“The issue for system integrators is that manufacturers tend to charge a premium for chipsets,” states Bürkert. “For a network containing multiple devices, this can result in a high initial purchase cost. In a system incorporating 20 valves, for example, a corresponding number of manufacturer chips would be required to ensure seamless communication.

However, there are other ways to ensure peer to peer communication. Open data communication protocols such as CANopen provide a solution. Manufacturer and open data communication protocols can be combined within the same network, reducing reliance on premium chipsets without comprising functionality.

EDIP platform

Bürkert achieves this with its EDIP platform, built on the CANopen protocol, which allows intelligent networking of multiple Bürkert devices. “Instead of relying on chipsets to ensure communication with the PLC, EDIP utilises a gateway that allows information provided by devices in CANopen to be translated into whichever manufacturer protocol is desired for the PLC, and vice versa. Therefore, only one manufacturer chip installed in the gateway is required for seamless integration. EDIP provides full monitoring and control functionality, without a reliance on premium chipsets.”

The immediate consequence of this technology, adds the company, is that it lowers the total cost of implementing an Industry 4.0-ready network. This cost saving is transmitted directly to the end user.

However, with EDIP, this is achieved without any compromise in functionality. “The PLC still functions in its native protocol, whether that be PROFINET, EtherNet/IP, Modbus TCP or PROFIBUS. It provides the same parameters and information, with no disadvantage in terms of writing programmes for the PLC either. Communication is seamless.”

Benefits of standardised interface

EDIP’s proficiencies are said to extend well beyond savings at initial purchase. “The platform standardises the interfaces between all Bürkert devices, allowing for simplified integration and operation. With Bürkert offering a wide range of valves, flowmeters and controllers that are all EDIP compatible, system integrators have great flexibility in terms of device choice, too – all from a trusted source.”

When a network is created in EDIP, all parameters and configurations are saved in the gateway. EDIP can recognise when a valve or other device is removed from the system for maintenance, informing operators. Once a repair is complete, the device can be reinstalled into the system and it will be instantly recognised by EDIP. Furthermore, if a complete device replacement takes place, EDIP will recognise the new addition and automatically apply saved parameters and configurations to it seamlessly. This greatly expediates any device integration.

EDIP allows maintenance flags or parameters to be set up in the network, alerting end users to equipment that has passed a certain threshold. For example, a simple on/off valve could be assigned a maximum number of cycles before inspection is required; or a valve that is neither fully on/off in operation could be assessed on distance travelled. EDIP offers the functionality to carry out diagnostics, find faults and trigger proactive preventive maintenance support or ensure a fast response to any failures.

Cost-effective standard

While EDIP provides all the functionality expected of an Industry 4.0 monitoring and control network, its cost-effectiveness and standardisation of interfaces equips end users with a potent combination, Bürkert concludes. “Reducing reliance on manufacturer chipsets by utilising gateways translating manufacturer protocols to CANopen and vice versa ensures increased value. This further enhances the benefits of integrating devices within a digital network by reducing equipment cost and simplifying implementation, maintenance and expansion.

“Furthermore, the innate features of the platform, such as maintenance flags and diagnostics, provide additional advantages, ensuring a cost-effective network of devices not just at point of purchase, but throughout operation.”

Fluid Control Centre

1 Bridge End

GL7 1QY

UNITED KINGDOM

+44 (0)1285 648720