Posted to News on 6th May 2022, 09:27

New feature for predictive maintenance is simple to implement

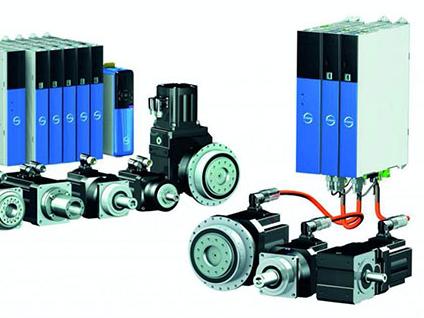

Stober has developed a new feature for the predictive maintenance of its geared motors that needs no additional sensors, cables, software, or other hardware components.

For this IoT solution, a configuration from the electronic nameplate of the geared motor can be applied or the data can be downloaded via an online service. Users do not need any special know-how to evaluate the data and handle it accordingly.

Stober Predictive Maintenance is an efficient solution – without external sensors or additional wiring – which is already installed in new 6th generation drive controllers. Drive controllers of this series that are already in use will receive the function via firmware update, which will be activated automatically. The required data are either stored in the electronic nameplate or can be easily downloaded via an online service.

This new Stober update monitors the geared motors of the drive system, their life performance being calculated using model-based analysis and output in the drive controller software via a life performance indicator, which is a value between 0 and 100 percent. When the calculated life performance reaches 90 percent, the software issues a recommendation to replace the geared motor and, if present, also provides a controller for it in the form of a readable parameter.

Another convenient feature of Stober Predictive Maintenance is the load matrix, which is a solid database for recording real-world load situations where the cumulative load condition of the drive system is continuously documented over the entire operating time. The load matrix can be exported via the drive controller, or controller, as a JSON or CSV file, then imported into Excel, for example, for editing and visualisation. This provides users with a diagram that they can interpret.

Based on the load matrix, users can detect any errors or anomalies and determine possible causes. For example, say a system is configured for 90 percent torque load, if this value increases significantly over time, it could indicate a defect.

On this basis, users monitor the geared motor and receive reliable information about the actual load situation of the machine. They do not require any special know-how, and even without subsequent data processing or complex analysis functions, significant improvements in quality and efficiency are possible.

The drive controller software provides users with a Predictive Maintenance wizard that is easy to operate and the load condition of a machine can be displayed as a 3D histogram.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Centrix House

Upper Keys Business Village, Keys Park Road

Hednesford

WS12 2HA

UNITED KINGDOM

+44 (0)1543 458 858