Posted to News on 20th Oct 2020, 08:56

New fire-resistant enclosure maintains electrical system safety

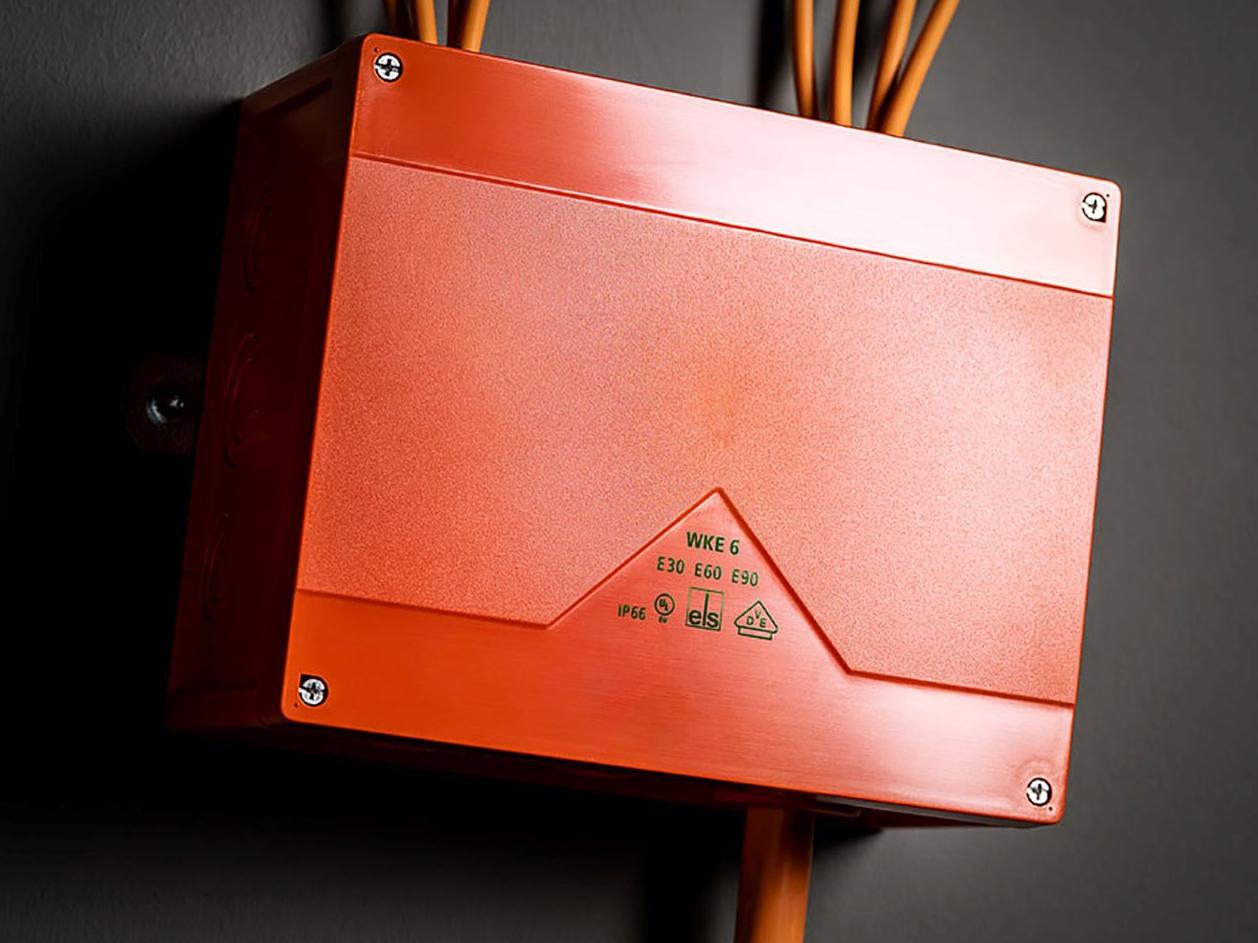

Spelsberg says that its new fire protection enclosure has improved the safety of electrical systems, enabling the control of alarm, evacuation and extinguishers for a minimum of 90 minutes in the event of a fire

The newly upgraded WKE enclosures, part of the Lifeline range of products from Spelsberg, meets E30 to E90, the strict standards which ensure that functional integrity is sustained for a minimum of 30, 60 and 90 minutes in the event of fire. This means that Lifeline enclosures ensure the operation of alarms, emergency lighting, acoustic systems and evacuation-compatible lifts, typically required for 30 minutes. Smoke and heat extraction systems, water extinguisher pressure systems, as well as fire brigade lifts, can also continue to operate for a minimum of 90 minutes as a result of the protection provided by Lifeline.

To achieve this level of fire resistance, traditionally electrical conduits have been encased in concrete. However, limitations of this technique include an obvious lack of flexibility where the design of the encasement and wiring architecture is required before the building is erected. From a safety perspective, while concrete encasement protects from fire, ithey don’t necessarily prevent electrical circuit failure.

Instead, while retaining the flexible installation advantages of externally mounted enclosures, the new additions to the Lifeline range are constructed from thermoplastic polycarbonate, selected for its high heat tolerance. As polycarbonate is non-conductive during a fire, it also removes the risk of short circuit. Internally, the construction includes terminal block clamps made from ceramics whihc are resistant to high temperatures. To protect the enclosures from unauthorised access, sealing is achieved through integrated openings.

Lifeline meets British Standard BS 7671 for electrical safety, as well as the German electrical circuit fire safety standard, DIN 4102-12. The strength and durability of polycarbonate also means that the new Lifeline enclosures have a high resistance to impact, meeting IK08, and high protection against ingress including strong water jets, meeting IP66. This also means that Lifeline can be mounted in an outside environment. Lifeline is certified in accordance with VDE and ULEU, as well as EN 60670 and IEC 62208.

Spelsberg says that the flexibility of the Lifeline enclosure means that it can also be installed when and where required without the need for significant prior planning of cable architecture and protection. Mounted on a fire-resistant wall or ceiling, the enclosure is attached by two external, pre-fitted lugs, which can be rotated around 90 degrees. The terminal block can be adjusted on the base carrier through three positions, 0, 45 and 90 degrees, thanks to a single, central screw and sliding bracket.

Lifeline enclosures are pre-assembled, so only wiring is required. For easier wire routing and attachment, the terminal block can be set on the mounting rail in the high position. Alternatively, the mounting rail can be set in a second, low position, ideal for specific applications such as D0 fuse mounting. The design also provides space for installing single and double terminals, as well as fuse holders. Meanwhile, the enclosure cover can be kept safe during wiring with the optional cover-retaining strap. Pre-punched, patented knock-out membranes on the enclosure housing enable simple and clean cable routing and installation. The exterior of the housing also provides labelling fields, where lettering can be applied with adhesive strips or waterproof pen.

The new Lifeline enclosures are available in a variety of formats and sizes range from 100 x 100 x 70 mm up to 250 x 200 x 120 mm. Spelsberg UK says that it also offers project-planning for safety systems and can provide in-house expertise to ensure correct and rapid fitting for more complex projects.

Unit 1B Queensway Business Park

Hadley Park West

TF1 6AL

UNITED KINGDOM

+44 (0)1952 605849