Posted to News on 4th Feb 2021, 11:15

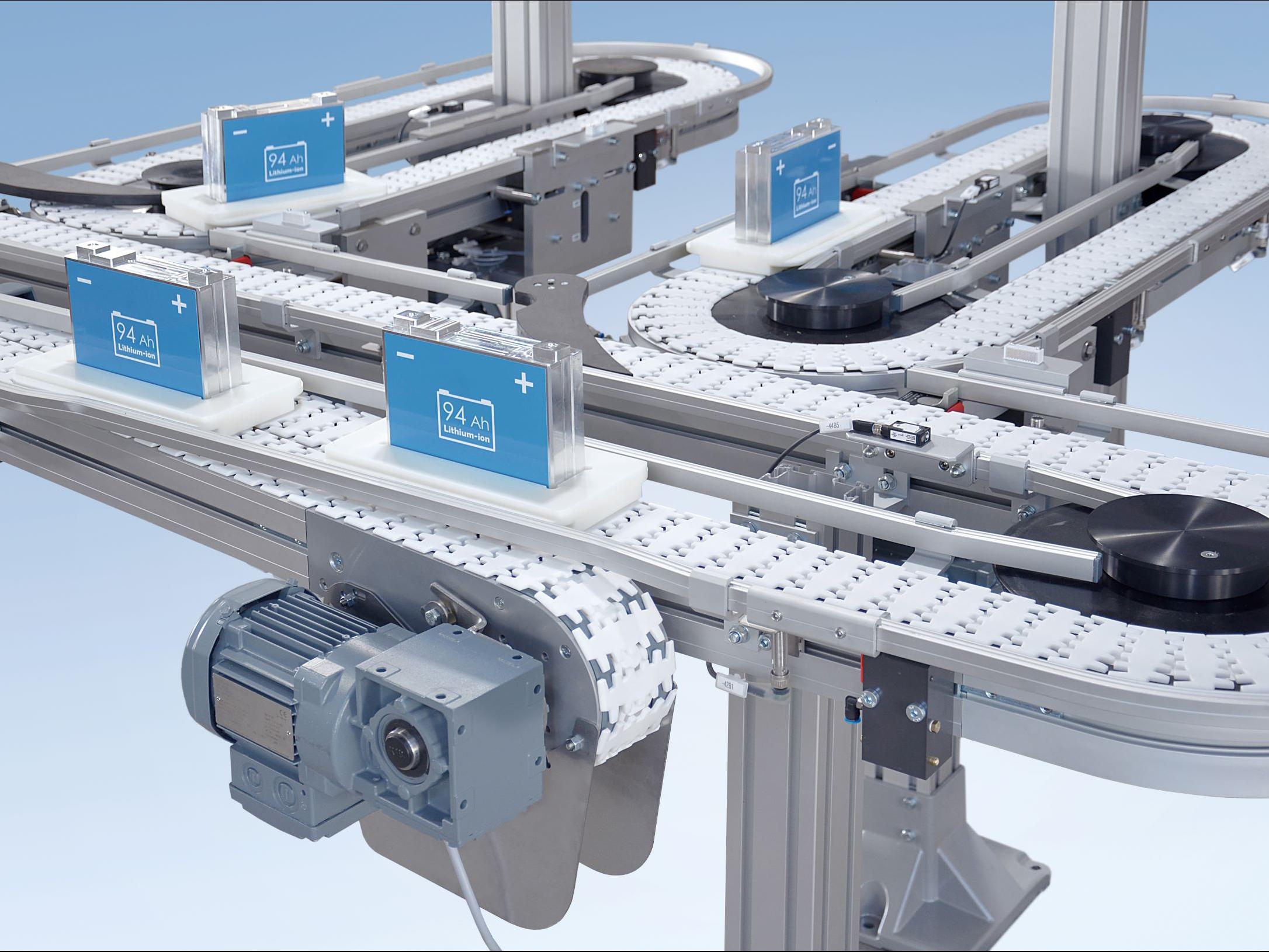

New flat top chain conveyor system grows with your requirements

mks new Versaflex flat top chain conveyor system is said to be both versatile and flexible. Find out why here...

mk’s new versatile and flexible flat top chain conveyor system - Versaflex - is a conveyor system that has been designed by the company to grow with the requirements of customers. It features a modular design and this, together with standardised modules and components, are said to make it simple and cost effective to integrate the system into just about any production process, as well as being able to adapt and expand it.

Handily, mk says that it is compatible with systems that are currently available on the market. The single-track design and curve radii starting at just 150 mm allows for complex track designs and the chain itself runs on wear strips to ensure low wear. It can be operated at speeds of up to 50 m/min and system lengths up to 40 m with just a single drive.

The system is said to be flexible and efficient with chain widths from 44mm to 295mm available together with a large selection of drives, bends, cleats, side rails and other accessories. Gentle transport and exact positioning using workpiece carriers are provided as standard and the company points out that Versaflex has already been used very successfully by an mk subsidiary for many years.

mk highlights Versaflex as an economical solution for complex track designs that offers simple and fast configuration and commissioning. Versaflex can be quickly adapted to new production and environmental conditions, saving energy and space and accessories such side rails can be easily attached in the slots on the conveyor frame profile.

The conveyor chains are made from POM and are available in a wide variety of designs for virtually all applications. The company offers an adhesive surface for inclines, with steel covering for sharp-edged parts or flocked covering for transporting delicate items. In addition, a large number of different cleats are available as well as rollers in a wide range of dimensions for accumulating products: alternatively machine builders can specify flexible cleats for implementing clamping conveyors. Further, chain links with embedded magnets can be used to transport magnetisable parts which may prove attractive in some applications.

Areas of application for mk’s Versamove include primary and secondary-packaged products from, among others, the food, pharmaceutical, chemical or consumer goods industry. Also for the transport of workpiece carriers in assembly lines such as those in the automotive industry and for the linking of machines across other manufacturing industries.

To ensure the precise positioning of products, workpiece carriers can also be transported on the mk A08 system. The system is 85 mm wide (chain width 83 mm) and is designed for products weighing up to 10 kg per carrier. The carriers have a standard width of 150 mm and are guided by side rails and positioned exactly in three levels in the locating stations. So the products are fixed, buffered and transported gently, safely and accurately. The workpiece carrier can be customised and equipped with individual fixtures. The locate station can be freely positioned without changing the side rails and a positional accuracy of ± 0.1 mm can be achieved by lifting the workpiece carrier off the conveyor chain.

The Versaflex workpiece carrier system is claimed to offer simple and accurate positioning for automated processes, with stability good enough for products with unfavourable geometry. Gentle product transport can also be achieved for sensitive product surfaces. Versaflex workpiece carrier systems offer safe transport even with changes in position, higher machine autonomy and buffer function for cycle decoupling in a manufacturing process.

Unit 11-12 Wolds Farm Business Park

Kinoulton Lane

NG12 3EQ

UNITED KINGDOM

+44 (0)1949 823751