Posted to News on 21st Oct 2020, 08:57

New-generation bullet train runs on NSK bearings

High-performance bearings from NSK are now operational in the newly developed N700S Shinkansen (bullet train)

Japan’s new N700S Shinkansen – often referred to as a ‘bullet train’, entered service on the line between Tokyo and Osaka on 1st July this year. The N700S marks the start of a new era for the Japanese railway system, being the first completely new Shinkansen design from the Central Japan Railway Company in 13 years. NSK bearings have been used extensively on the new design with its focus on safety, stability, comfort and environmental performance. Bearings for railway applications obviously contribute directly to safe operation, and reliability is important too, together with the ability to perform at high travelling speeds. Improved energy efficiency and reduced maintenance requirements remain further essential elements.

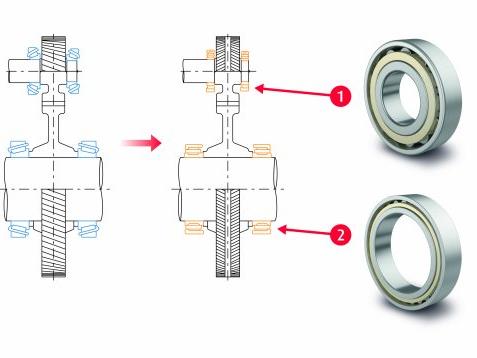

The demands placed on railway bearings are especially apparent in bullet trains, given that they transport large numbers of passengers at high speeds over great distances. The ‘S’ suffix of the new-generation N700S bullet train stands for ‘Supreme’, signifying a progression in design, technology and comfort. Bearings from NSK are employed in the gearbox, axle and traction motor assemblies. In respect of the gearbox, the N700S is the first Shinkansen in operation with helical gears that have been replaced by herringbone gears: they are stated to provide increased reliability with lower noise output. Gearbox bearings are subjected to shock loadings and vibration, so exhibiting a long operational life under these conditions is a priority. NSK has been supplying tapered roller bearings for helical gears in bullet trains for decades. Drawing on this experience, the company has subsequently designed a special flanged cylindrical roller bearing for the N700S’s herringbone gears that delivers longer life with lower heat generation and reduced maintenance compared with the previous generation products.

Further benefits of the gearbox bearings used on the N700S are stated to include improved seizure resistance, which has been achieved by optimising the design of areas that do not contact the flange face. In addition, a high-strength machined brass cage featuring NSK’s proprietary R-pocket technology reduces internal stress in the cage structure itself. For the axles, NSK double-row tapered roller bearings which were used in the previous Shinkansen are said to have been further improved by the company to deliver even higher reliability and reduce maintenance costs. Lower heat generation leading to longer life is stated to be another notable attribute. Turning to the traction motors used in the N700S, NSK cylindrical roller bearings and deep groove ball bearings feature outer rings that are plasma-sprayed with a ceramic coating. This is said by NSK to increase reliability by preventing any opportunity for electrolytic corrosion to occur.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Office 4, Arlington Business Park

Gateway 1000

Whittle Way

SG1 2FP

UNITED KINGDOM

0800 634 1909