Posted to News on 26th Jan 2012, 14:26

New HepcoMotion Bleed Lubrication System for linear slides

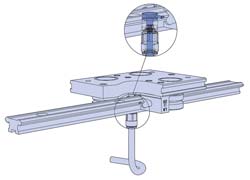

HepcoMotion is launching the Bleed Lubrication System for dual-vee linear slideways, which the company claims to be unique on the market. With machine builders and production engineers under pressure to maximum machine uptime, it is desirable to avoid stopping production for routine relubrication of linear motion systems, hence HepcoMotion's latest development.

Now available as an option for all its core linear motion products, the HepcoMotion Bleed Lubrication System provides constant lubrication to the slide vee face via specially machined channels that are connected to an external supply via lubrication inserts.

Lubrication is delivered directly to the vee face and, in turn, it is picked up by the carriage and bearings as they pass over each lubrication exit point. In this way lubricant is carried around the entire system.

This new HepcoMotion lubrication system also saves on the number of lubricators or cap seals normally fitted to each carriage, thereby reducing system friction and associated cost, as it is the slide that is responsible for delivering the lubricant to where it is needed. These components do still play a vital role, however, so it is recommended that one in four carriages are fitted with lubricators or cap seals in any system in which bleed lubrication is being used.

Bleed Lubrication options

Slide lubrication inserts are available with either an M5 thread or 4mm diameter bore with O-ring seal to suit the installed linear system. Lubricant can be supplied via a grease- or oil-filled pressurised canister that dispenses lubricant at a controlled rate, or via a centralised lubrication system.

HepcoMotion Bleed Lubrication can be specified on the GV3 precision slides, HDS2 heavy-duty slide system, PRT2 ring-and-track system, SL2 stainless steel and corrosion-resistant range, and also the DTS driven track system. In addition to slides with dual bleed lubrication holes, double-edge slides are also available with single bleed lubrication holes. These can be positioned on either vee and anywhere along the length to suit the application. Single-edge slides can also be supplied with the bleed lubrication facility. Both double- and single-edge slides are provided with a range of dedicated inserts.

High-load linear actuator applications can also take advantage of this continuous lubrication feature, as it can be specified for the HepcoMotion HDCS and HDLS driven systems.

Full details and technical specifications for the HepcoMotion Bleed Lubrication System are available in a new Bleed Lubrication data sheet, which can be accessed by going to www.hepcomotion.com/PRT2datauk and selecting reference data sheet No.6.