Posted to News on 19th May 2022, 16:00

Nord Drivesystems exhibits at ‘all about automation’ 2022

On 29 and 30 June 2022, Nord Drivesystems will present the DuoDrive geared motor, the energy-efficient IE5+ synchronous motor, the new decentralised NORDAC ON frequency inverter and the NORDAC PRO SK 500P control cabinet inverter, at ‘all about automation’.

A compact and regional trade fair in Hamburg, all about automation connects manufacturers, distributors and service providers for industrial automation and communication from the northern region. All about automation highlights the practical exchange of information about systems, components, software and engineering for industrial automation.

Here, Nord Drivesystems offers innovations such as the patented DuoDrive: the geared motor integrates a high-efficiency IE5+ synchronous motor into a single-stage helical gear unit housing and sets new standards with regard to performance, installation space and version reduction.

The result is optimised system efficiency, high power density, compact housing dimension and very low noise emissions. Elimination of many wearing parts results in lower maintenance. In combination with simple commissioning of the complete solution via plug-and-play, this results in a significant decrease of the total cost of ownership.

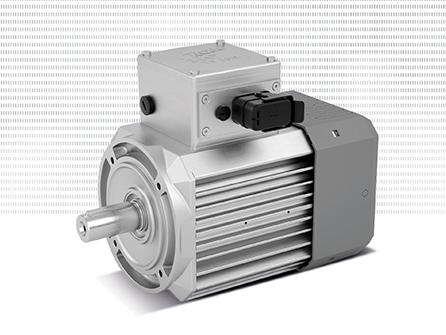

The energy-efficient IE5+ permanent magnet synchronous motors achieve their high efficiency that, at times, is significantly above efficiency class IE5 via a wide torque range – and they are optimally suitable for operation in the partial load range. The new IE5+ motors are equally interesting for both intralogistics and hygiene-sensitive areas in food and pharmaceutical industries.

The new motor is available in ventilated or smooth versions up to a power of 4.0 kW. The IE5+ synchronous motors can be combined with all gear units and drive electronics from Nord Drivesystems in a modular system. If required, they are provided with a very smooth surface or the nsd tupH surface treatment.

Another new product is the decentralised NORDAC ON frequency inverter. It is characterised by an integrated Ethernet interface, full pluggability as well as a very compact design while providing an economic plug-and-play solution for IIoT environments. The frequency inverter can be mounted directly on the drive housing and covers lower power ranges of up to 1.0 kW. NORDAC ON was designed for use with asynchronous motors, whereas NORDAC ON+ is intended to be combined with synchronous motors, and supplements the NORD high-efficiency portfolio around the new IE5+ motor generation.

NORDAC PRO SK 500P frequency inverters, meanwhile, are equipped with an integrated multi-protocol Ethernet interface, a multi-encoder interface for multiple axis operation and a USB interface for voltage-free parameterisation. The variety of interfaces and functions is characteristic: Various inverter versions can be optimally allocated to various application requirements. Plug-in control, safety and option modules ensure maximum flexibility and the compact book-size design format enables space-saving installation in control cabinets.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>