Posted to News on 5th Sep 2022, 11:04

Norelem Academy helps to overcome the skills shortage

The Norelem Academy is supporting the bridging of the skills shortage by sponsoring and championing manufacturing and engineering projects for early career professionals and aspiring engineers in the making.

The manufacturing industry is currently facing a challenging skill shortage. With fewer young people getting into the industry and seemingly more barriers for them to get in the first place, it is extremely important that industry leading companies support the development of new talent.

Norelem Academy is the skills education arm of German standard component manufacturer Norelem. Since 2016, Norelem has taken more active steps towards progressing its talent development services, and the Academy is only one part of that. Norelem Academy offers educational services at every level: from general education to vocational schooling and technical schooling, Norelem Academy aims to offer support and development opportunities to engineers at all stages in their professional career. In addition, the Norelem Academy offers specialist lectures and points users to the free CAD data available on the norelem website.

Over the past few years, Norelem Academy has taken on the task of sponsoring students and educational services to further enhance the development and skills of prospective technicians and engineers across multiple fields of manufacturing and engineering. One example of this is Norelem’s role as primary sponsor of VDI’s racing camp, where students get an opportunity to prepare themselves for the Formula Student competitions by testing their built vehicles in a competitive setting.

Norelem Academy itself is always looking to sponsor new projects to provide funding and training to early career professionals and students within the manufacturing industry. A recent example is the supporting of the HTL Rennweg in Austria. The project was an ambitious aerospace engineering project to develop an aircraft shunting trolley that the students involved had dubbed “towy”. The trolley allows for the safe manoeuvring of single-engine aircraft by individuals, which means a single user can fully concentrate on the safety and possible dangers of a collision instead of the pressure inducing task of moving the aircraft to the respective parking position. Therefore, safety is increased from when the aircraft lands, up until it reaches its final parked position.

The project made use of many of Norelem’s standard components, such as idler sprockets to set the correct chain tension of the shunting trolley, which improves the function of the drive, reduces chain wear, and therefore increases the service life of the chain

However, the activities of Norelem Academy span much wider than that, and internationally too. For example, the Academy recently provided both the standard and the operating components for use in an orthopaedics, trauma surgery, and sports medicine project to a student in Spain.

Orthopaedics is the field of medicine that deals with the treatment of congenital malformations, the prevention and therapy of chronic diseases, and injuries to the musculoskeletal system. So, anything that can be done to counteract these problems, or at least prevent them from deteriorating, is a great achievement in medicine.

A forward-thinking student at the University of Valladolid, Spain, is working on the design, calculation, and prototyping of a mobility mechanism for the ankle joint. The prototype calculates the positioning of patient’s ankles and feet malposition to counteract problems such as clubfoot.

The goal of this project is to perform a scan of the joint in preparation for the subsequent creation of a custom orthosis to correct the foot's abnormal alignment. The usage of an FDM 3D printer is appropriate for the construction of the mechanism, because the Norelem CAD data is provided. The prototype is created and built using CAD software, and the different prototype parts are printed and put together utilising Norelem standard and operating components.

Norelem supports this student project by providing worm gears and spur gears which are used to transmit and calculate the force transmissions of the ankle joint’s movements. This means the forces can be precisely measured and recorded, which can establish any possible issues with the patients’ foot alignment. These measurements can then be used to create a custom orthosis for each individual patient.

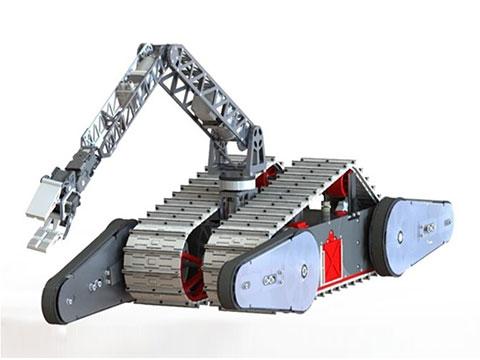

As well as sponsoring projects such as those of HTL Rennweg and the University of Valladolid, Norelem Academy takes great pride and joy in supporting student’s participation in events and competitions, such as the Robocop Rescue League competition. The student competition tests various crisis situations using either autonomous or remote-controlled robots. The competition aims to set new milestones in the field of disaster rescue and to ensure that projects from academic research are promoted to use in the real world.

The Res.Q Bots team, consisting of students from FH Campus Wien, made use of Norelem toothed belts, which were installed in a robot to transmit the torque of the motor to the shafts; Norelem axial ball bearings were used for the bearing of the wheels and to ensure good rolling behaviour. Additionally, the team made use of Norelem circlips for shafts, which prevented axial displacement and secured the bearing to the main structure.

Norelem Academy is also sponsoring the manufacturing and engineering projects that are pushing the boundaries of what can be achieved. One such project, currently taking place at the Technical University of Munich, aims to use new innovations and future technologies to create the fastest tunnel boring machine in the world; and are getting leaps and bounds closer to achieving their goal by using Norelem’s versatile standard and operating components.

The project is a non-profit association with the goal of working towards a greener future by making people waste less time in traffic. The team views the construction of tunnels as a future technology that can be shaped and driven by innovation. To reach this goal, the team aims to build the world’s fastest tunnel boring machine.

The machine makes use of Norelem’s plain bearings to counteract the sliding friction between the pin and the bush. It also makes use of Norelem’s shim washers to achieve a high chemical resistance and reduce partial vibrations. Shim washers allow bolts to be mounted and adjusted on the grip pad, and the connection of the jacking system to be adjusted.

Norelem Academy is extremely proud to be supporting engineering and manufacturing projects at all stages of education and at all stages of the project’s development. It is in the best interest of the Norelem Academy to help to bridge the skills gap, but also of Norelem itself to facilitate the manufacturing and engineering needs of new projects and developments.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>