Posted to News on 10th Mar 2017, 16:07

NSK ball screws replace hydraulics in powder presses

Switzerland-based Osterwalder AG is replacing hydraulic drives with servo-electric drives featuring NSK HTF series ball screws in its latest range of powder presses. As a result, users of the new systems can achieve a reduction in energy consumption of around 80 per cent and produce pressed parts with far higher dimensional accuracy. This reduces the amount of finishing work, such as grinding with diamond wheels, and cuts process and material costs.

Metal-cutting tools such as carbide inserts are typically produced using powder press technology. This entails filling a metal powder alloy into a die and pressing into the desired shape before final sintering. At the end of the process, tool manufacturers require inserts that are as close as possible to the final profile, as additional finishing is both expensive and challenging; the sintered inserts are extremely hard.

Focused on providing solutions that overcome issues such as these is Osterwalder AG, which is based in Lyss, around 15km from the Swiss capital, Berne. To help deliver extra precision into the powder pressing process, the company recently took the decision to introduce new drive systems: the CA SP Electric and CA HM Electric series. This "Direct Drive Technology' (DDT) with servo-electric motors and NSK ball screws, replaces the former hydraulic drives, which are now only used in presses requiring exceptionally high forces.

Using DDT, pressing is performed with far greater accuracy, as Michael Sollberger, development engineer at Osterwalder, confirms: "We can position these systems to within 1um and achieve very high repeatability levels."

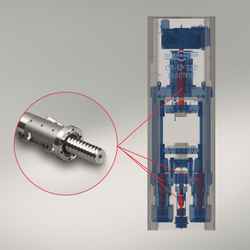

Heavy-duty ball screws from NSK's HTF (High Trust Force) series are responsible for the linear motion of Osterwalder presses. Precise synchronisation of movement is important as any interruptions or irregularities in the process can lead to dimensional errors, or even cracked inserts during sintering.

HTF ball screws also permit very high traverse rates, thus helping to minimise cycle times. Furthermore, very high axial force can be delivered, with patented geometry ensuring equal load distribution over all of the balls in operation. In combination with special ball separator technology, this prevents premature wear and assures very high reliability.

Energy savings

Along with high precision and good controllability, users of Osterwalder powder presses featuring the new drive systems can also achieve energy savings of around 80 per cent. A powder press with a hydraulic drive and pressing force of 160kN has an energy consumption of up to 15kW. In contrast, a servo-electric system requires only 2.5-3.5kW. Since Osterwalder customers typically operate between 10 and 70 powder presses, the potential cost savings are vast.

A further advantage of adopting the ball screw drive approach is that the presses now take up much less space. In addition, servicing can be reduced because there are no hydraulic control valves or other high-maintenance components, while working temperatures are more constant as no heat is being produced by the hydraulic system. Noise reduction is another benefit, as Mr Sollberger explains: "Our hydraulic systems operate at just below the 75dB limit, whereas the servo-electric systems are very quiet, only 58 to 60dB."

Various NSK ball screws are used in the CA SP Electric and CA HM Electric series, moving the upper and lower die together simultaneously. Osterwalder first introduced servo-electric drives on its 160kN presses, then its 320kN models. In total, more than 100 such presses are now operating successfully in the field. Looking ahead, this trend could continue as NSK states that pressing forces of up to 4000 or even 5000kN can be sensibly transmitted with the HTF series.

HTF ball screws are available in a variety of diameter, recirculation systems, lead and seal options, and can be complemented by heavy-duty NSK ball screw support bearings (TAC series) and linear guides (RA series). NSK is the only company that can deliver a complete mechanical powertrain from a single source, matching the different parts.

As well as carbide pressed parts, the technology is equally applicable to components made from iron powder, ceramic and magnetic materials. HTF series ball screws have also been adopted widely by manufacturers of plastic injection moulding machines.

For more information about NSK HTF series ball screws, visit www.nskeurope.com.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Office 4, Arlington Business Park

Gateway 1000

Whittle Way

SG1 2FP

UNITED KINGDOM

0800 634 1909