Posted to News on 2nd May 2017, 12:10

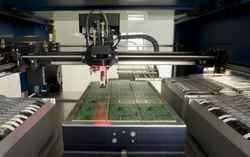

NSK Linear Guides solve pick-and-place machine problems

Faced with repeated failures of its linear guides, an established and reputable manufacturer of surface mount technology (SMT) pick-and-place machines turned to NSK for the solution. After identifying the source of the problem, NSK was able to recommend its NH Linear Guide series. Today, several thousand such units have since been supplied to the customer, with no premature failures reported.

The pick-and-place units deployed in SMT assembly machines must withstand high mechanical stresses. A typical machine operating in the electronics sector is able to place components on printed circuit boards at speeds of more than 50,000 components per hour, with high precision. Furthermore, these machines can handle components from up to 200 feeders (rolls of electronic parts) simultaneously.

With so many electronic components being placed so quickly, it is inevitable that problems sometimes occur. This was the case with the pick-and-place system on a new series of SMT assembly machines being developed by a European OEM. The manufacturer experienced a very short lifespan from its original linear guides, while replacing them with others from a second manufacturer yielded no improvement. What 's more, neither supplier could find the cause of the failures or offer a solution to the problem.

Following these disappointments, the OEM contacted NSK, which tasked a team of experts with analysing the failed components. The conclusion, determined primarily by the damage exhibited on the components, indicated that the moment (tilting) load was too high. The cause of this was attributed to misalignment errors within the pick-and-place system.

As a result, NSK recommended switching to its NH Linear Guide series, which is not only purpose-designed for high-speed applications, but offers self-aligning capabilities. A special type of grease was also implemented as it could provide better lubrication properties than standard grease in applications featuring short strokes and shock loads.

The project proved highly successful. Once the NAH20ANZ type guides from NSK began to enter service, the OEM experienced no more breakdowns. Moreover, several thousand installations later, the NH Linear Guides are proving to have a long lifespan.

For more information about NSK's NH Linear Guide series, visit www.nskeurope.com.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Office 4, Arlington Business Park

Gateway 1000

Whittle Way

SG1 2FP

UNITED KINGDOM

0800 634 1909