Posted to News on 21st Nov 2008, 14:41

ODS electric linear drives offer much-improved performance

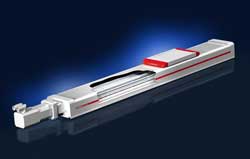

Parker-Origa (previously Hoerbiger-Origa) is introducing a new generation of powerful modular electric linear drives that combine performance with application flexibility. The Origa Drive System (ODS) provides a complete range that encompasses screw-, belt- and linear motor-driven systems, providing users with a combination of speed, precision and load-carrying capacity for a wide variety of applications. In addition, innovative design features provide increased flexibility in terms of assembly and disassembly, higher levels of ingress protection as standard, simpler lubrication and a range of optional add-ons to meet the broadest spread of application requirements.

Much of the design focus for the ODS has been on increasing repeatability, accuracy force and speed across the range, with the various models offering significantly higher performance than previous generations. As an example, the ball screw-driven ODS-SB version offers a repeatability 2.5 times better than the previous generation, and exerts forces up to 66 per cent higher. This performance boost is reflected across the range.

Conventionally, users turn to linear motors for high speed, highly dynamic positioning, toothed belt drives for fast-moving medium loads, and screw drives for medium to high loads due to the lower speed and higher positioning precision offered by this technology. However, by boosting the performance in all these areas across the whole ODS range, Parker-Origa is giving designers more freedom to choose the technology that best suits their needs, rather than being forced along a particular path because of traditional performance compromises.

Guidance options

One of the keys to the increased performance is a newly developed guide system, with options for a plain bearing guide, roller guide or recirculating ball bearing guide. The guide takes all of the load to allow much higher performance ratings over longer rail lengths.

There is a 'basic profile' version available for supported lengths, and a 'reinforced profile' version for unsupported lengths, allowing the profile to be used in freestanding applications without the need for additional profiles or specially manufactured supports to reinforce the drive.

A standard bore pattern simplifies mounting of the drive, but individually tailored bore patterns can also be provided to meet individual application requirements, or to make it easier to align combinations of axes. Furthermore, an alternative fixing system using T-slots in the body profile provides an almost unlimited range of assembly options.

Ingress protection

Considerable design effort was put into developing a fully integrated unit that is protected against dust ingress. The ODS is available either with covers or as an open version. The uncovered version provides IP20 protection and the covered version provides IP54 protection.

Parker-Origa's option of a specially designed cover provides much more reliable protection in real-world application environments throughout the operating life of the drive. All additional fittings can be located beneath the covers to avoid the damage that could occur in harsh or damp environments if they were mounted externally.

Attention to design has also delivered an improved external lubrication facility for the IP54 drives, allowing lubrication to be carried out quickly and simply from a central unit through external nipples without the need to remove the protective covers.

Position sensing

Further evidence of the modularity of design is the free choice of mounting position for limit switches, giving users increased freedom to set both end position and reference position sensing points. Both reed and electronic switching versions are conveniently terminated at plug connectors located in the actuator end cap. For applications involving high speeds or heavy loads, the end-of-travel limit switches can be combined with integral shock absorbers for reliable impact protection.

Where precise positioning throughout the length of the drive is required, Parker-Origa offers the option of a contactless, electromagnetic incremental distance measuring system, combining ease of fitting with high precision and easy integration into the underlying control system.

For applications where the drive has to be stopped and held under load, pneumatic or electric brakes are available. The holding brakes are suitable for use with the drives in both horizontal and vertical mounting arrangements, accurately holding the driver or the workpiece being carried at precise positions, which may be critical points of a transfer or machining process.

Follow the link for more information about the Parker-Origa ODS (Origa Drive System).

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>