Posted to News on 14th Dec 2020, 15:00

Off-the-shelf multifunctional machine vision system

SICKs newly-developed MQCS (Modular Quality Control System) is said to be an off the shelf multifunctional machine vision system

MQCS is delivered by the manufacturer as a ready-to-use package of hardware and pre-written software. Suitable for code reading, 2D or 3D inspection duties, SICK claims that the MQCS reduces cost and the development time needed to set up automated quality inspection and logistics applications.

In another example of sweet success, it was originally developed as a solution for the non-contact 3D inspection of chocolate moulds in the confectionery industry. Here, the MQCS demonstrated its versatility to be adapted for other applications such as “right product/right packaging” code matching, counting and aggregation of varied packages, or monitoring the cycle life of materials handling equipment and other 3D inspection and measurement tasks.

SICK says that with the MQCS, users can take its ready-made package and adapt it easily for the task in hand. It is scalable, described as easy to configure with other sensors or devices as necessary and also has the versatility to integrate into higher controls. Advantages to users include the accuracy of a high-speed, high resolution vision sensor (such as the Ranger 3) without the need for the extensive programming skills that this would normally require.

Customers purchase the MQCS as a complete system with pre-written software, control cabinet with touch-screen HMI, and a SICK (Telematic Data Collector) application controller, which can be combined with SICK vision sensors such as the LECTOR image-based code reader and the Ranger 3 camera. With a PLC interface module for real-time processing of sensor outputs, and a network switch, it is said to be easy to configure even complex 2D and 3D image processing into production controls.

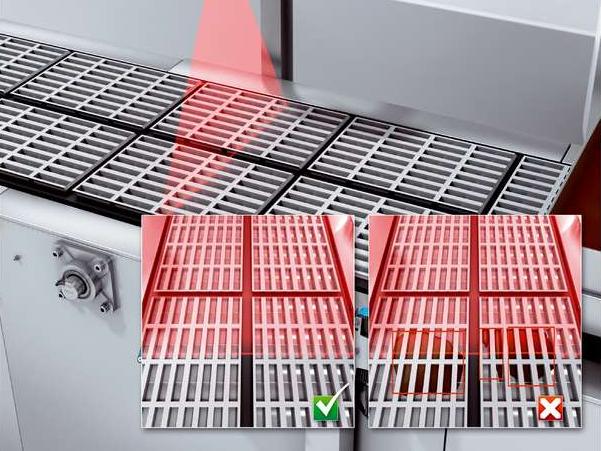

Along with the basic software modules, additional application plug-ins enable specific machine vision tasks such as pattern matching, shape evaluation, counting, OCR verification or quality inspection to be easily configured via the simple set-up. System data is automatically logged and easily viewed via the HMI touch screen on the control panel supplier, or a web server. The system’s digital outputs enable users to set up alerts and alarms to monitor process quality and efficiency.

The SICK MQCS is supplied with basic functions that can be supplemented by software modules and hardware components as required for the individual application. It therefore particularly useful as an easy to integrate, stand-alone solution that can be used to upgrade existing machinery.