Posted to News on 9th Oct 2015, 11:51

Omron demos innovative, problem-solving technologies at PPMA

Omron stand B34 at PPMA 2015 will include three important demonstration areas, showing end users and OEMs how they can implement a traceability system using product serialisation. The displays demonstrate how to meet common traceability requirements, ways to implement more flexible packaging lines through the use of an innovative, universal transparent object detection sensor, as well as how to implement standalone machinery safety systems that will meet the needs of today whilst providing the flexibility for being open for future integration.

With counterfeiting of popular drugs and cosmetics now becoming a real issue, and after several high-profile food and beverage industry product recalls, a number of initiatives and legislative measures are being put in place to ensure improved inspection and traceability. Most notable among these measures are the Falsified Medicines Directive (FMD) in the pharmaceuticals sector, and the GS1 standards being adopted across the wider packaging, food and beverage industries.

With the implementation date for FMD now set at 2018, and the various implementation requirements settled upon, it is vital for companies large and small to put strategies and technologies in place to address this important legislation.

While traditional lot and batch-level traceability provides a level of supply chain risk management, FMD imposes a requirement for item-level serialisation, where individual packs are marked with unique, machine-readable identifiers that will provide traceability from the point of sale all the way through the manufacturing processes. This will enable the authenticity of the medicines to be checked anywhere in the supply chain, and whether those products have been distributed via legitimate channels.

Achieving this level of traceability through serialisation presents key challenges in managing the data internally, with supply chain partners and with consumer-oriented servers. At PPMA, Omron will demonstrate an integrated system for traceability through serialisation, built around their FH vision system and a middleware product. When combined, the technology provides a robust and reliable track and trace system in line with FMD requirements.

The demonstration will show a number of different packages on a turntable, each with unique product codes. These will rotate under the FH vision camera which will check the code for reliability and validity. The code will then be reported to the middleware package, which will show the codes and marry them up with batch and supply information.

Reduced complexity and effort

In particular, the demonstration highlights the benefits of working with an automation vendor such as Omron rather than a dedicated supplier of all-in-one systems. As an element of Omron's wider Sysmac automation platform, the FH vision system for traceability through serialisation can be easily integrated and adapted to meet specific customer requirements with significantly reduced complexity and effort. The demonstration also highlights the simplicity of integrating with third party software, making it easy to adapt to meet future requirements.

Additional benefits of the FH-based system include its fast teaching method which simplifies set-up and enables fast product changeovers, so reducing downtime and making it easy to adapt to changes. The FH vision technology also boosts productivity by providing ultra-fast code recognition.

Further, the FH traceability through serialisation system can also provide trend data that can help in optimising productivity and reducing downtime. In particular, it can monitor the print quality, grading and position of the printed code, giving early warnings for preventive maintenance before errors occur.

Marketing manager Dan Rossek says: "There are a lot of companies who haven't wanted to jump in too soon in implementing traceability through serialisation strategy and risk the draft FMD legislation changing in the meantime. But with most of the debates on the legislation settled and the implementation date of 2018 firmed up, it is imperative that companies large and small put a strategy in place.

"With a solution built around Omron's FH vision technology, users can benefit not only from a class-leading track and trace solution, but also simple integration into the wider automation system, with full scalability to start small and expand the system as required, with additional cameras and inspection tasks."

Transparent object detection for food/drinks packaging

Omron has developed a new sensing technology which looks at changes in the polarised state of the reflected light. This addresses a key challenge within the packaging industry - to reliably detect a whole range of different transparent products.

Conventional sensing systems for transparent objects look at differences in intensity of the reflective light, but the result is that a sensor which is optimised for glass bottles will be much less effective and reliable with plastic bottles and transparent film. Users would need different sensors for each medium. But today's packaging lines are optimised for flexible manufacturing and are increasingly handling a whole range of different products on a given line. For reliable object detection, this could mean having to change and retune the sensor for each different product coming down the line.

With the new Omron sensing technology, users can standardise on a single device, confident that it will work with any transparent product, without the need for any retuning. The highly reliable detection helps to improve the flexibility of machinery and saves time during set-up.

On its stand at PPMA 2015, Omron will have a demo cell for this innovative sensing technology, and is challenging visitors to bring their own difficult target media to the show. Marketing manager Dan Rossek comments: "We have yet to find a transparent material that the sensor can't detect!"

Visitors will be able to present a transparent product or material, and see for themselves on a PC screen the disturbance of the light, with a large difference that will clearly indicate the stability and reliability of detection. Further, by working reliably even under difficult NEC lighting conditions, the demo will also highlight the immunity of the sensing technology to ambient light.

Standalone machinery safety

A dedicated safety demo area on the Omron stand at PPMA will show how users can reap all the benefits of networked, integrated safety systems in a standalone format. While there are undoubtedly advantages to having the standard control and safety control on a single networked platform, in many applications it is desirable to keep the two separate.

This is particularly important where the safety side of a machine control system needs to be expanded on machines that are being (or will be) upgraded or modified, but where it is undesirable to have to change the standard control architecture.

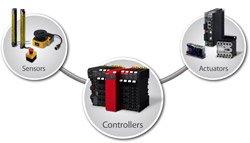

Omron's Sysmac safety technology is capable of being tightly integrated within the wider Sysmac control platform, or operating in a standalone format. Omron's NX-S standalone safety controller is a logical expansion of the Sysmac standard control platform, and enables the integration of safety circuits that are tailored to current needs and existing machine concepts, yet which are open for future integration.

Combined with the existing family of safety and standard NX I/O, the safety controller allows users to benefit from all of the advantages of the wider Sysmac platform. This means using the same software as all other Sysmac products for programming, commissioning and debugging, which reduces learning time and investment, and simplifies further integration and modification in the future.

In the safety demo area of its stand at PPMA, Omron will show how the NX safety controller networks with a range of safety I/O, including sensors, emergency stop switches, light curtains, safety relays, interlocks, presence detectors and vision systems.

Go to www.industrial.omron.co.uk to learn more about the company's offering, or visit Omron on stand B34 at PPMA 2015.