Posted to News on 21st Oct 2021, 08:57

On the optimum path

A look inside new machining strategies and specially designed milling tools

Toolpath optimisation, through the use of CAM systems, has been commonplace for decades. In the last 10 years, shops have begun to pair that capability with relatively new machining strategies and specially designed milling tools to optimise rough-machining operations.

Rob Mulders, product manager Solid End Mills at Seco Tools, his much expertise in this area. “Dynamic milling or advanced roughing are the typical descriptions of this time and cost-saving machining strategy. These CAM-based rough-machining, or dynamic milling, strategies are ones that centre on a cutting tool’s arc of contact and its average chip load.

"By adapting the tool’s arc of contact via its CAM-generated toolpath, roughing speeds are increased, effectively controlling process temperature, applying higher feeds per tooth and increasing depths of cut to significantly shorten overall part machining cycle times — all without placing any additional strain on machine tool spindles.”

Arc of contact and thermal load

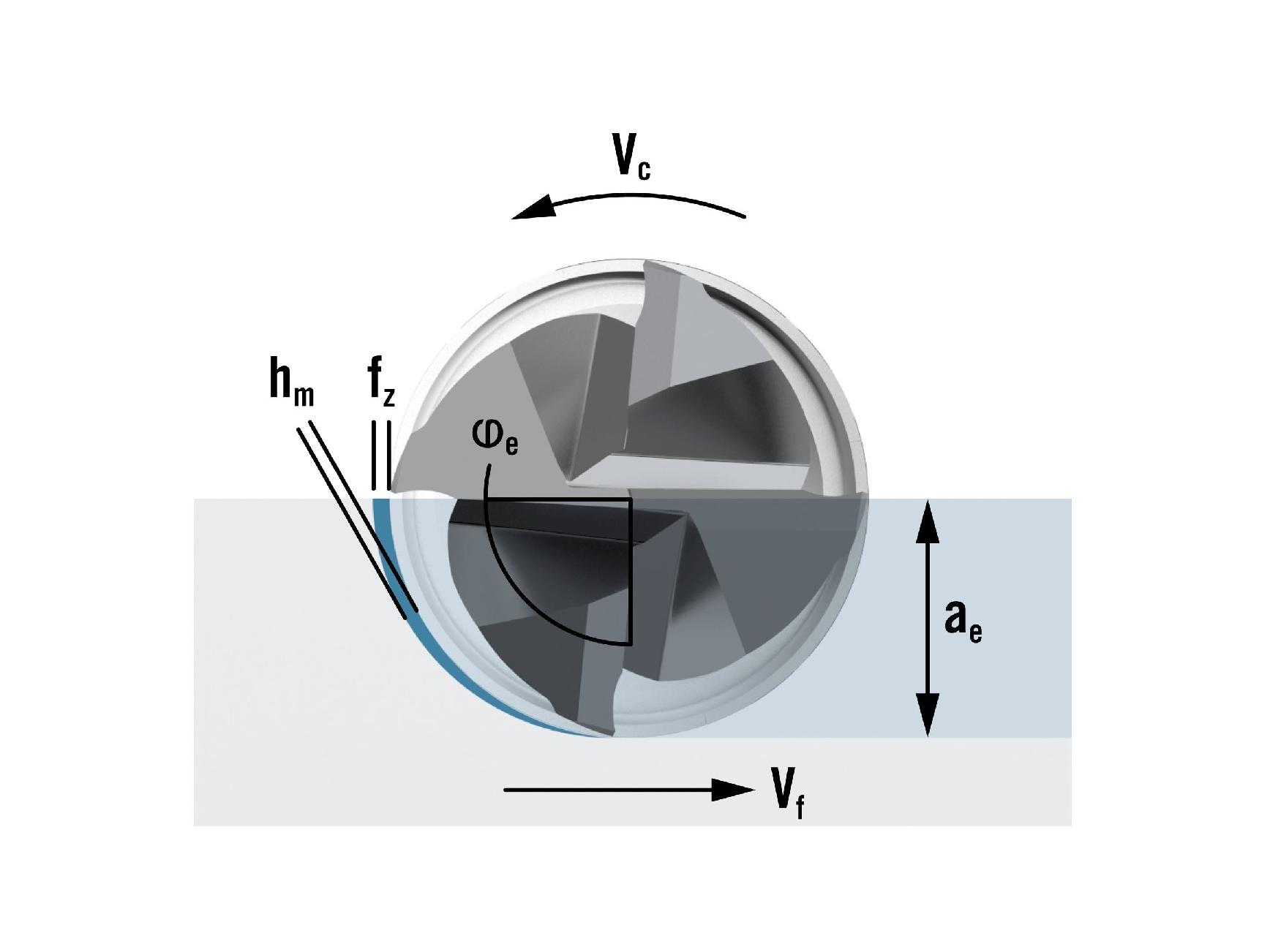

“A cutting tool’s arc of contact is an independent variable that influences thermal load on the tool and is the key to optimised roughing operations. Maximum arc of contact on any tool is 180 degrees (its diameter). So, at a full arc of contact, the radial cutting depth (or cutting width) is the same as the cutter diameter and represented by ae (radial depth of cut) = Dc (cutter diameter).

“In adapting the arc of contact, shops can reduce the amount of heat generated during roughing operations,” states Mulders. “As the radial depth of cut decreases, so does a cutter’s arc of contact. A smaller amount of contact results in less time in cut and, therefore, less heat between the tool’s cutting edges and the workpiece it is machining. What occurs at the same time is the tool’s cutting edges have more time to cool from the time they exit the cut, revolve around and re-enter the cut. These lower machining temperatures, in turn, allow for increased cutting speeds and shorter cycle times.”

Average chip thickness and physical load

A cutting tool’s average chip thickness (hm) is based on physical load and maintained through a combination of feed per tooth and arc of contact adjustments, he points out. “Because chip thickness constantly changes during cutting, the industry uses the term average chip thickness (hm). A full 180-degree arc of contact will generate the thickest chips at the centre of the cutter’s width. So, a smaller arc of contact – less than 90 degrees (e, engagement angle) – reduces the chip thickness and allows for increased feed per tooth (fz) as a compensation.

“For example, consider a 10-mm diameter cutter slotting (full arc of contact), at 50 percent of its full arc of contact (5-mm), the cutter is generating its largest average chip thickness/heaviest physical load. In the first 90 degrees the cutter is up-milling until a maximum chip thickness (fz) is reached and continues with the second 90 degrees in down-milling where the chip thickness decreases again to 0," adds Mulder.

Less material, faster pace

“If the ae drops (ae < 0,5xDc) to, for example, 1 mm (10 percent), then average chip thickness will become smaller, allowing for faster roughing by applying increased feed per tooth (fz). While the cutter removes less material, it does so at a much faster pace. Also, there is less tool and machine spindle strain generated when compared to taking heavier radial cuts at slower feed rates. In dynamic milling roughing applications, a lower AEMX (radial depth of cut) also allows for an increased APMX (axial depth of cut) for even faster material removal.

To access the rest of Rob Mulders’ in-depth insights, click here.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>