Posted to News on 17th Jan 2012, 22:04

Online tool calculates bearing friction quickly and accurately

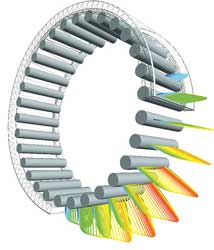

Schaeffler has released a revised version of its Bearinx rolling bearing calculation and simulation software, which includes new functions for calculating friction. Bearinx-online Easy Friction helps engineers to identify and maximise the potential for energy efficiency improvements within a machine or system, particularly when used early in the design process. For example, after using the software, the user may decide to specify rolling bearings with reduced friction characteristics, or to downsize the bearings and/or other related system components.

Available online and free-of-charge to users and customers, the new Bearinx-online Easy Friction software module enables users to calculate the energy efficiency of different rolling bearing designs in any application. Users can register now at bearinx-online-easy-friction.schaeffler.com.

Bearinx-online Easy Friction takes into account the internal load distribution of the bearing and contact pressures on the raceways and ribs, with the actual rolling element profiles. The new software module utilises a friction calculation theory based on physical algorithms confirmed by a series of comprehensive values from tests on rolling bearings. Bearing life is calculated according to ISO/TS 16281.

Easy to use

The software's intuitive menu structure and navigational tools enable users to enter data quickly and easily for bearing modeling, bearing selection and operating conditions. The bearing design for an elastic shaft system, for example, can either be modeled with a locating/ non-locating bearing arrangement or as an adjusted bearing arrangement. The geometrical data of INA and FAG rolling bearings is uploaded automatically from an integral database. The user enters the operating data such as the loads on the shaft system, shaft speed, the internal clearance and axial preload of the rolling bearings. Lubrication and cleanliness details can also be specified.

In addition, users can exchange any saved files with Schaeffler's Engineering Service department in order to produce an optimum bearing design. Powerful servers at Schaeffler then perform the actual bearing calculations. The most important results are displayed in a results window, with the input data and calculation results documented in a PDF file.

Until now there were two main methods of calculating the friction of rolling bearings: the catalogue method or by using special multi-body simulation (MBS) programmes. The catalogue method uses an empirical approach, which enables calculations to be performed quickly using low model accuracy. MBS programmes, however, offer very high model accuracy but require longer calculation times.

New approach

The new Bearinx-online Easy Friction module takes into account both rolling and sliding friction, in solid body, mixed and fluid friction cases. Elasto-hydrodynamic theory (EHD) lies at the core of the friction calculations. This deals with the formation of a lubricant film in the contact points of bodies under high loads when rolling at high speeds. EHD theory includes the formation of a hydrodynamic lubricant film and elastic deformation of the contact bodies. Every single contact in the bearing is analysed, since stress, sliding speed, viscosity and temperature are not constant over the contact surface of a body. All frictional forces on the discreet points of the contact surface are then available in the calculation results.

Follow the link to register for Bearinx-online Easy Friction or call the Marketing Department on +44 (0)121 313 5870 or email [email protected].

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>