Posted to News on 29th Sep 2023, 10:30

Optical quality inspection system for up to 4,000 parts per minute

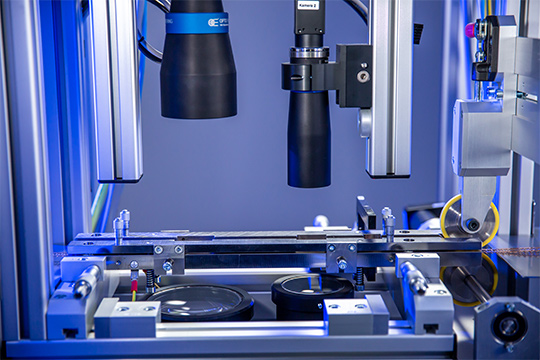

With a width of only 600 mm and a fast throughput time, the KVC 621 SE quality inspection system from Kistler is ideally suited for the mass production of stamped parts. The system ensures the reliable quality testing of each of the up to 4,000 pieces that get processed every minute.

In many production environments, every square inch counts – and that’s equally true for manufacturers of stamped parts, who also have to use the space available for their production processes as efficiently as possible. Kistler has developed the compact KVC 621 SE optical inspection system specifically for quality control in mass production.

Within its housing, which is only 600 mm wide and 900 mm deep, the easy-to-install test system performs all inspection tasks at high speed. Thanks to its fully electromechanical drive, the KVC 621 SE doesn’t rely on compressed air like pneumatic solutions.

An additional digital slack loop control allows users to further save valuable space and reduce the number of inspection steps. Kistler offers fast delivery and commissioning – within four to six weeks – of the KVC 621 SE, a standardised optical inspection system that features three integrated camera stations and a sensitive touchscreen.

In the quality control system, the stamped parts undergo thorough optical inspection. Cameras capture the workpieces from various angles; the KiVision image processing software developed by Kistler analyses the images and detects deviations in dimensions and contours as well as relevant surface defects. With KiVision 5.3, users can create their own command macros to handle complex inspection tasks more easily. Depending on the nature of the inspected parts and user requirements, the software can also provide AI-based anomaly detection, which is particularly helpful in applications involving previously unknown or frequently changing surface defects.

During operation, the system can inspect up to 4,000 stamped parts per minute. Thanks to an integrated safety concept, the reliability of the inspection process is guaranteed even at these high cycle times: Using close PLC monitoring of the individual process steps, the test system ensures that every single workpiece is checked.

Manufacturers who opt for solutions from Kistler also benefit from comprehensive industrial expertise from a single source: Service specialists from Kistler help to optimally set up new inspection processes or to further improve existing ones. This support covers everything from the initial inquiry to the selection of inspection parameters and installation, to maintenance and machine upgrades. Kistler also provides a wide range of on-site trainings and consulting services for manufacturers’ employees.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

13 Murrell Green Business Park

London Road

RG27 9GR

UNITED KINGDOM

+44 (0)1256 741550