Posted to News on 26th Sep 2023, 09:16

Pallet system for round battery cells

When a manufacturer of batteries for electric vehicles needed a pallet circulation system with different interfaces to facilitate automated inspection of the battery modules, it turned to mk Profile Systems.

The manufacturer joins together individual round cells to make battery modules. The round cells needed to be inspected fully automatically in the goods receipt area.

A robot takes several individual round cells as a set from the packaging and places them on the conveyor system. The cells first need to be separated in order to ionise them against electrostatic charge. They are then placed in individual compartments of a tray.

The individual cells are subjected to different tests along the cycle. The trays must be stopped and positioned at the stations so that the tests can be carried out automatically. The circulation system also needs a mechanism by which to separate defective parts.

A tray holds 14 cells and must complete the entire cycle within 15 seconds. On account of the many test and robot stations along the system, the space available on site is very limited.

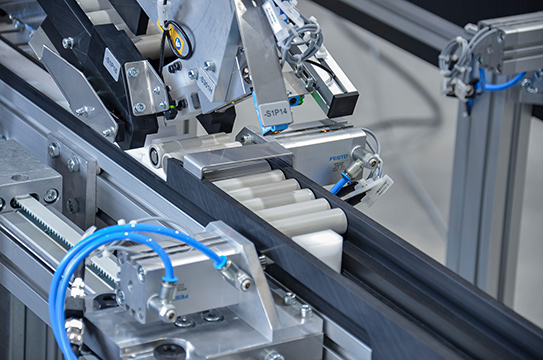

An mk ZRF-P 2040 timing belt conveyor was used to implement this pallet circulation system. Index stations allow the trays to be positioned within an accuracy of ±0.2 mm. This ensures that the automated checks can be performed reliably. A ramp serves as an infeed into the conveyor system.

A robot places the cells onto this ramp. They are separated and then slide into the individual compartments of the tray. Due to the short cycle times and the limited installation space, a shuttle was constructed to transfer the trays to the workpiece carrier return line. The conveyor technology transports the trays into the shuttle where they are then quickly transported to the parallel conveyor system for the return journey using a linear unit. At the end of the line, the cells are removed from the trays so that the trays are available for loading again.

mk was able to provide a solution which was a bespoke design configured from its standard construction kit. The solution has given the customer short cycle times for high output quantities.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

AdaptTech Manufacturing Solutions

Unit 11-12 Wolds Farm Business Park

Kinoulton Lane

NG12 3EQ

UNITED KINGDOM

+44 (0)1949 823751