Posted to News on 10th Nov 2008, 13:24

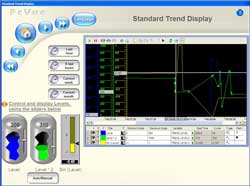

PcVue V.8.2 converts data to man-machine interfaces

ARC Informatique's latest version of its PcVue software has a number of innovations that help to reduce the cost of running and implementing process control projects. PcVue V.8.2 is claimed to be the only SCADA tool in the world that is totally compatible with AutoCAD, and also enables the conversion of FactoryLink data. It also supports VMware, which allows a single PC to manage several virtual machines, where before several dozen machines were needed.

Created in 1985, PcVue is said to represent a new generation of SCADA software that is characterised by advanced ergonomics and powerful tools based on object-oriented technology. It considerably reduces the development and implementation time of industrial process control applications, where it is used for assembly lines in chemical, pharmaceutical and agri-food plants. To develop and further evolve PcVue, the teams at ARC Informatique used their accumulated experience based on the fact that there are over 35,000 licensed copies of ARC Informatique products installed worldwide.

One PcVue V.8.2 innovation is the recent development of its Smart Generator tool. Since the creation of this control application, Smart Generator has allowed the use of data from software platforms such as Wago Codesys, Schneider Electric Unity, ISaGRAF, Echelon or all types of PLC program to create automatic man-machine interfaces (object models, behaviours, etc). With version V.8.2, PcVue integrates the existing data of old, obsolete control platforms, such as FactoryLink, as well as AutoCAD files and more general files (.dwg or .dxf). Thus control models and associated objects can be automatically generated from the AutoCAD files.

Virtual machines

PcVue V.8.2, which aims always to simplify implementation and reduce operating costs, now supports the virtual environment VMware. Instead of having several machines distributed around the control site, which are generally under-used and rapidly becoming obsolete, a single central PC is used, simulating the other machines. One part of its resource is allocated to each virtual machine.

To add a control application, all that is needed is a simple copy and paste from the existing virtual machine on the PC, which supplies it to the user's terminal. In the case of process changes (production rate, new conditions, etc) it is enough to adjust the allocated resources through the central PC to this virtual machine.

Finally, the Web Services connectors are improved through an open web connection interface that allows third-party applications, such as ERP or MES, to connect easily to PcVue V.8.2 independently of the number of machines or their geographic location.

Further new functions are proposed, including:

- Integration of Windows Domain Authentication and Active Directory into the user 's rights. The software searches the user rights on the server that manages the profiles

- Managing historical data under the SQL server. The data is therefore easily and rapidly exploited

- Improved control management. When a new line is calibrated all the machines likely to interface with it find the correct parameters and connect directly to the system

PcVue V.8.2 will be presented at the SPS exhibition in Nuremberg, from 25-27 November 2008, on Stand 7A-602.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>