Posted to News on 21st Apr 2023, 13:30

Photoelectrics prove vital in checking test-tubes of blood

When designing an automated handling system for picking and placing test-tubes of blood, a manufacturer of automated laboratory equipment turned to Contrinex for a system to ensure the vials were orientated the correct way around.

Part of an in-vitro diagnostics system, the reliability, long operating distance and high resolution of Contrinex’s LRS-3030 reflex analogue photoelectric sensors are trusted to detect the orientation of the vial and that a cap is fitted.

To automate the placement of small test tubes into carrier racks, test tubes are picked from a conveyor. The vials must be placed into the racks the right way up, with the cap uppermost. A feed conveyor aligns the test tubes, but at this stage, they are presented in one of two orientations, with the cap coming before or after the rest of the vial.

The shape and material of the test tubes make measuring them difficult because they are round, transparent and filled with liquid in varying quantities, with indistinct contours and a lack of planar surfaces. Camera-based identification systems or profile scanners were considered to be too expensive and the customer wanted a solution that was both economical and reliable.

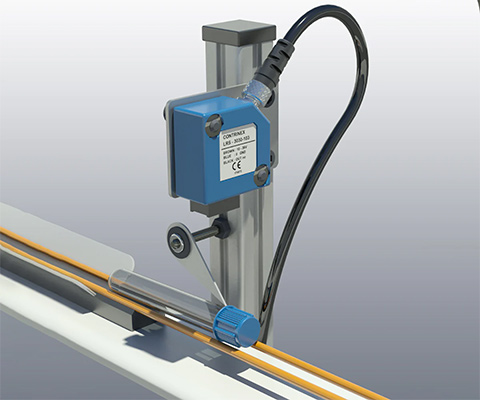

A lightweight lever is used to trace the contour of the test tube as it passes beneath it on the conveyor. The side of the lever facing the photoelectric sensor provides a consistent planer surface, which helps ensure reliable distance measurement of the lever, as it rises and falls, tracing the tube’s profile.

The sensor detects the fitted cap because it has a diameter 2mm larger than the test tube. Therefore, the machine’s PLC polls the sensor’s analogue value every 20 ms to determine the position of the larger cap mathematically. Based upon this, the machine rotates the test tube if required, so that all vials are placed into the rack correctly. The automation will pause the conveyor if it detects a test tube without a cap, because it did not see the increased deflection in the lever from the cap’s larger diameter.

Integrating the analogue output from the sensor to the PLC is simpler, quicker and so lower cost than using a vision or profiling system. The reliability of the Contrinex photoelectric sensor enables an automated system which inserts one test tube, correctly oriented, into the carrier rack, every second.