Posted to News on 31st Jan 2019, 12:27

Phytron stepper motors, precision gear units used in Mars lander

For a small number of motion control applications, project success is only confirmed long after delivery - so no compromise whatsoever can be tolerated with design integrity, manufacturing quality and reliability. This is especially true for many projects undertaken by Phytron GmbH, the extreme environment motor, drive and motion systems designer and manufacturer, represented in the UK by Mclennan.

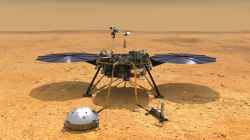

For example, Phytron's development, design and supply of deep space-prepared stepper motors and gear units for NASA's InSight Mars lander began in 2013, working with the Max Plank Institute for Solar System Research (MPS) on the levelling system for the SEIS (Seismic Experiment for Interior Structure) seismometer. With several European and American partners collaborating on the technological development of the SEIS project, the ultraprecise seismometer is capable of capturing sub-nanometre level ground motion from marsquakes, meteorite impacts, local events like dust storms or landslides, and even the tiny tidal deformation of Mars induced by its moon Phobos. Delivery to MPS took place well before Insight's launch in May 2018 and in November last year the successful landing of the spacecraft was followed by confirmation that the seismometer was operational early in January 2019.

No strangers to such extended project success timescales, and with well-developed and highly proven manufacturing and test procedures that ensure the reliability required for such extreme environment applications, Phytron has supplied over 250 motors for space applications and many more for other equally demanding motion control tasks.

Stepper motors and gear units

Extensive testing

Space-prepared motion components from Phytron are typically designed for use in ultra-high-vacuum with intensive radiation hardening and for temperature extremes of 573K for the motor winding down to 4K ambient (300degC to -270degC). Gear units include special lubrication and construction in materials including high-quality stainless steel and titanium. Of course, cleanliness during and after manufacture is paramount for such components. Outgassing and vacuum conditioning includes particle removal assisted by UV light, aided by alpha wipes and ionised gaseous nitrogen before and during assembly in Phytron's clean room. Testing and quality assurance is carried out in-house using Phytron's extensive test facilities or with the customer, and can include environment duplication where possible. Packaging includes double-bagging with the first bag purged with dry nitrogen before heat sealing with a desiccant pack and a humidity indicator placed in the second bag.

Non-space applications

Many of these manufacturing procedures are also used for other extreme environment motion control applications found in cryogenics, particle accelerator research, nuclear engineering, medical equipment and other equally demanding industries. Phytron's certifications include DIN EN ISO 9001 and DIN EN 9100 'Aircert'. The full product range covers standard and specialist-grade stepper motors and complete actuator assemblies with compatible stepper motor drives, gear units and sophisticated multi-axis motion controllers with optional Labview programming.

Mclennan has worked closely with Phytron for several years as a customer as well as a full distribution and support partner since 2017, and can boast several years' experience specifying and integrating the German specialist's standard and extreme-grade motion components. Mclennan has over 40 years' experience working with long-term, complicated technological projects such as this, so the partnership with Phytron is ideal.

Other cutting-edge instruments deployed on the InSight lander that contribute to measuring Mars' 'vital signs' include precision temperature and tracking equipment. Further information on the SEIS instrument and all its participating partners can be found here. More information on the InSight mission is available at mars.nasa.gov/insight.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1, The Royston Centre

Lynchford Road

GU12 5PQ

UNITED KINGDOM

+44 (0) 1252 531444