Posted to News on 13th Mar 2018, 13:02

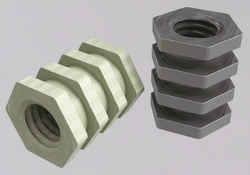

Plastic inserts: superlight, corrosion-free and cost-saving

When Fitsco developed its patent-pending new range of plastic threaded inserts in 2017, the company had no idea that one of the early applications would see the inserts specified for use at 50,000 feet and Mach 2+ on a front-line fighter aircraft. But that is exactly what has happened with the new LiteFit plastic threaded insert after it was specified as a 'metal replacement' part for an in-cockpit application on the Eurofighter Typhoon.

In order to achieve reduced overall platform conductivity and also to deliver a diminished radar signature, many modern military aerospace designs are moving away from metallic parts, where possible, and LiteFit helped achieve this on the Eurofighter.

The LiteFit range of plastic inserts was conceived and developed entirely in-house by the Fitsco R&D team at the company's headquarters in Shropshire and is claimed to deliver a substantial step forward in insert design. Fitsco Founder & CEO, Philip Schofield, says: "It opens up interesting new possibilities for design and production engineering teams in many market sectors by bringing a number of key advantages over standard metal inserts."

Weight reduction

Traditional metal inserts made of brass, steel and stainless are still used extensively in the joining of plastics. Despite the obvious weight penalty that comes with brass, steel and stainless, this aspect is often deemed immaterial or irrelevant for a variety of general industrial applications. However, design engineers seeking to reduce overall weight in applications where it does matter have so far been stymied when seeking a mechanical process to either join plastics and composites together, or attach other items to them using threaded inserts.

As a result, it remains common to see twenty-first century materials being joined using threaded insert technologies and processes that emanate from the 1950s - and with a commensurate weight penalty.

However, with the introduction of LiteFit, Fitsco points out that, compared with brass, steel or stainless steel threaded inserts, the new plastic product delivers an individual-item weight saving of up to 80 per cent. So now, where weight does matter, so does LiteFit.

Automotive lightweighting

Concurrent with the Eurofighter Typhoon application in the UK, another early enquiry has highlighted the weight-saving properties of LiteFit inserts. It came from an automotive manufacturer in the USA, where LiteFit plastic inserts are under active consideration for an application that will enable the manufacturer to convert from a metal fabricated part to a significantly lighter - and potentially more durable - plastic version instead.

'Standard' moulding operations usually involve the moulding of a blind hole followed by the installation of metal inserts. However, by installing the new LiteFit threaded inserts into the mould tool itself, a technical benefit can be gained by achieving better material-flow integrity around the area of the insert itself. Schofield says: "This increase in integrity has the potential to make a big difference in some cases." In addition to this design engineering advantage, he also points out that one of the other advantages delivered by LiteFit is the reduction of overall assembly costs. By having LiteFit installed as part of the moulding operation, OEMs can do away with the need for the additional installation equipment, time and labour needed to install metal threaded inserts after the moulded part has been made. On some projects this element alone can cost more than the original moulding did itself.

The advantages 'per project' can be readily calculated by production personnel and this aspect was also an additional key driver on the American automotive application previously mentioned.

Colour choice

Fitsco points to another advantage of LiteFit which at first glance may not mean a huge amount to many engineers or company bosses - but to those who need it there is much to commend it. LiteFit plastic inserts can be colour-matched to blend with the parent material into which the inserts are being installed. The company believes that for many manufacturers this could provide a quality of finish and visual appeal that has not thus far been obtainable using conventional metal threaded inserts.

Furthermore, as Philip Schofield concludes: "Our new range of LiteFit inserts are fully recyclable, food-industry compliant, have excellent chemical and corrosion resistance, and do not require plating. They offer good mechanical strength and are also great electrical insulators too. We are working on some interesting applications in the medical market as well as others in automotive and aerospace. And with all our inserts being made here at our plant in Bridgnorth, we also provide OEMs with an assured and swift response. Should design or application assistance be required we can be anywhere in the UK in a matter of hours."

Go to www.fitsco.co.uk to learn more about the company's LiteFit plastic threaded inserts.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit B, Middleblock, Knowle Sands Industrial Estate

Eardington

WV16 5JL

UNITED KINGDOM

+44(0)1746 769188