Posted to News on 24th Feb 2016, 11:12

Plug-and-play linear systems for production machines

In order to meet very short development times for machine tools and other special-purpose production machines, manufacturers expect their linear technology suppliers to offer not only linear components but also plug-and-play subsystems, engineering, drives technology and other technical support services, including final assembly, cabling, set-up of control parameters and commissioning.

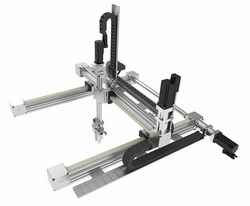

Schaeffler's Linear Technology division in Homburg specialises in ready-to-use, project-specific linear systems. An intelligent mix of customisable, high-performance linear system components from Schaeffler, plus mechanical and electrical drive elements from well-known suppliers and partners, form the basis of ready-to-use, cost-effective linear systems.

Schaeffler engineers can integrate a wide range of components and systems such as linear guidance systems, toothed belt drives, ball screw drives, planetary screw drives, measuring systems, rotary encoders, carriages, lubrication systems, end switches and covers into Schaeffler's in-house developed extruded aluminium profiles. In addition to standard components, Schaeffler also develops and manufactures customised linear systems that are optimised for the specific load scenarios using finite element methods. These linear systems are manufactured as plug-and-play electrical systems using a range of direct drives, servomotors, controls and sensors. Combined with Schaeffler's comprehensive range of rolling and linear bearings, as well as bearing expertise, the result is a range of innovative products with a high degree of integration.

Telescopic actuator: more space for machine tools

Compared with standard linear axes, telescopic axes offer significant advantages in that they do not extend over the whole travel distance and so can free up space for other machines and processes. When used as secondary axes, telescopic modules offer more options for machine tool designers such as the transfer of tools to areas behind protective walls or into different workspaces.

The MTKUSE series of telescopic actuators from Schaeffler is designed specifically for secondary axes such as pick-and-place applications or for tool transfer. Three precision linear ball bearing and guideway assemblies are arranged on top of each other such that the possible travel distance is more than twice that of the basic actuator. The linear unit can also extend in both directions. A geared servomotor is mounted on the outside of the aluminium profile and drives the actuator via a rack-and-pinion. On request by the customer, servomotors from different suppliers and suitably prepared, low-backlash precision planetary gearboxes can be fitted. End switches and distance measuring systems can also be integrated on request. An indirect evaluation of the frictional torque and therefore the condition of the bearing is also possible via the servo controller using current detection and position error monitoring.

High-precision linear table for precise, repeatable movements

Schaeffler's LTP series of high-precision linear tables are specified when tools need to be moved precisely and with high repeat accuracy during machining or inspection. The linear slide is supported by a high-precision machined aluminium plate on high-accuracy linear recirculating ball bearing and guideway assemblies. These assemblies ensure smooth, quiet running and a low displacement resistance. The LTP table is driven by a servomotor and a ball screw drive (a direct-drive version is also available). Distance measuring systems and position switches can be included if requested.

The LTP high-precision linear table is available in three sizes with a grey cast iron, vibration-damping option. The tables can be fitted with bellows or a telescopic metal cover for protection from foreign objects and liquids. A coupling housing (KGEH) is available for use as a universal, open interface to accommodate different servomotor suppliers. An indirect evaluation of the condition of the frictional torque and therefore the condition of the bearing (or spindle) is also possible with linear tables via the servo controller.

High-precision linear tables are also used as secondary axes in machine tools for transferring tools or to drive laser guidance systems for marking or coding of tools.

For more information about ready-to-use, project-specific linear systems, go to www.schaeffler.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>