Posted to News on 10th Feb 2021, 10:30

Push towards digital transformation

A flood of data is available on Industrie 4.0, but right now it is estimated that 90% of this data is not used

Industrie 4.0 has been a hot topic for some time, but progress has not been fast in achieving its objectives. Why is this so and how can this be changed and how can data be turned into structured and useful information?

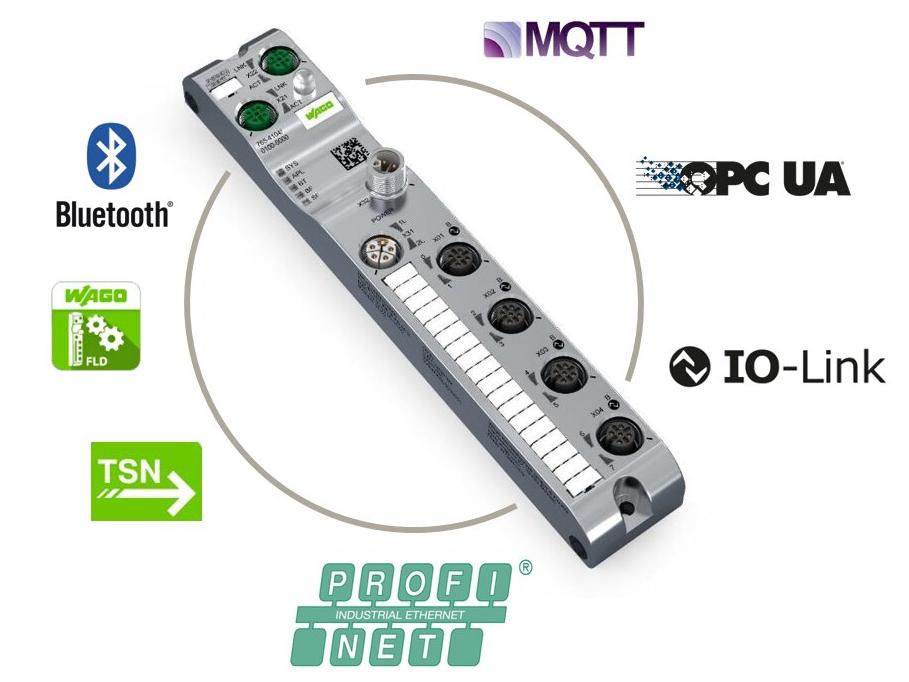

According to Karsten Schneider, chairman of PROFIBUS & PROFINET International (PI), it’s imperative that we understand and co-determine the entire scope of different topics in the field of industrial communication. “Communication from sensor to cloud is possible today already, with IO-Link as a widely spread sensor level protocol and PROFINET as the Industrial Ethernet backbone. Using OPC UA as the interface to IT applications, many standards are ready to be used.”

By way of example, PI references how Ethernet APL enables PROFINET to the Field of Process Plants. “Ethernet is the de-facto communication standard in enterprises, but it does not meet process automation requirements without modification,” says the company. “Ethernet with an Advanced Physical Layer [Ethernet-APL] will enable long cable lengths and explosion protection via intrinsic safety with communication and power over two wires.”

Also, PI points to how OPC UA Safety enables safe communication between controllers. It is a specification defined jointly by PI and the OPC Foundation. “OPC UA is already the most important standard for machine-to-machine communication. PI's many years of experience in the field of functional safe communication and PROFIsafe ensures that OPC UA Part 15: Safety meets all requirements of the IEC61784-3 standard [functional safety of fieldbuses].

“These include a maximum user data length of 1500 bytes, the creation of any network topology [star, line, grid], hierarchical safety IDs for simplified management of series machines and dynamic connection set-up with changing partners. Modular machines, Autonomous Guided Vehicles (AGVs), Autonomous Moving Robots (AMRs), tool changers etc benefit from this.”

Adds Karsten Schneider: “When the Industrie 4.0 project was started with lots of dedicated companies, its many different dimensions quickly became clear. On the one hand, PI must tackle the entire spectrum of industrial communication technology, but timely implementation can only occur in agile measures, based on existing technology. Due to the sheer size of this spectrum, this can only be done in close cooperation with other organisations.”

For more details, click here