Posted to News on 21st Oct 2021, 08:57

Quick-action integration via IO-Link

High-performance systems in the smart factory

The new MD7 system from Leuze enables powerful automation, says the company. “It is easy to integrate. IO-Link hubs are a cost-effective way for users to integrate additional digital sensors into the system, as required, and extend the system in a flexible and economical manner. This ensures that users benefit from consistently transparent data and processes.

“Thanks to the synchronised system of IO-Link masters and Leuze sensors, the connected machines have a high level of standardisation. All of the IO-Link modules, as well as connected sensors and actuators, can be quickly and easily commissioned, configured and centrally monitored via a web browser.

"Future security is guaranteed with IO-Link: backward compatibility means that, even years later, sensors with older dates of manufacture can be integrated into systems with the latest specification.”

IO-Link masters with multi-protocol capability

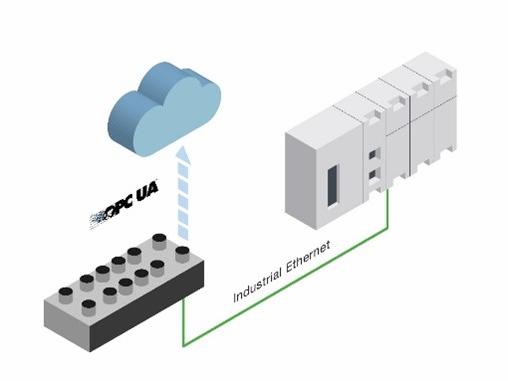

The IO-Link masters work with a variety of protocols, adds Leuze. “In a single device, they support the Ethernet-based fieldbus protocols for real-time communication. Communication via Modbus TCP is also possible. This can be used to connect to simpler PLCs, operating terminals or SCADA systems, for example.”

The advantage? “Flexibility when choosing the modules and a high level of standardisation with lower complexity. This reduces the stocking costs and streamlines maintenance.” A Leuze device model facilitates communication via OPC UA. This variant can be integrated directly into cloud-based systems and, with its web-based configuration, it can also be operated as a stand-alone solution.

The integrated web server with IODD interpreter allows all the connected IO-Link devices to be configured. The masters offer a multitude of ways to retrieve diagnostic and status information – either on the device or via a web server.

Flexible integration of sensors

IO-Link sensors integrated into the MD7 system transmit are said not only to process data, device information, diagnostic data and event messages: Ethernet-based I/O modules combine the data and connect the machine modules to the control and superior systems. This allows modular expansion of the machine. Time-saving and practical for maintenance: if a sensor needs to be replaced, the master automatically uploads the configuration to the new device.

Wiring made easy

The IO-Link modules have an M12 Power connector. This enables power connection of the modules, irrespective of the used Ethernet protocol. “The connectors deliver around 80% more power than 7/8" connectors. In daisy-chain applications – where hardware components are connected to one another in series – significantly more modules can be wired together, without requiring any additional power.”

This, states Leuze, reduces installation and wiring requirements and offers an advantage in cases where space in the machine is limited.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500