Posted to News on 20th Nov 2020, 08:57

Rational installation technology aids machine wiring

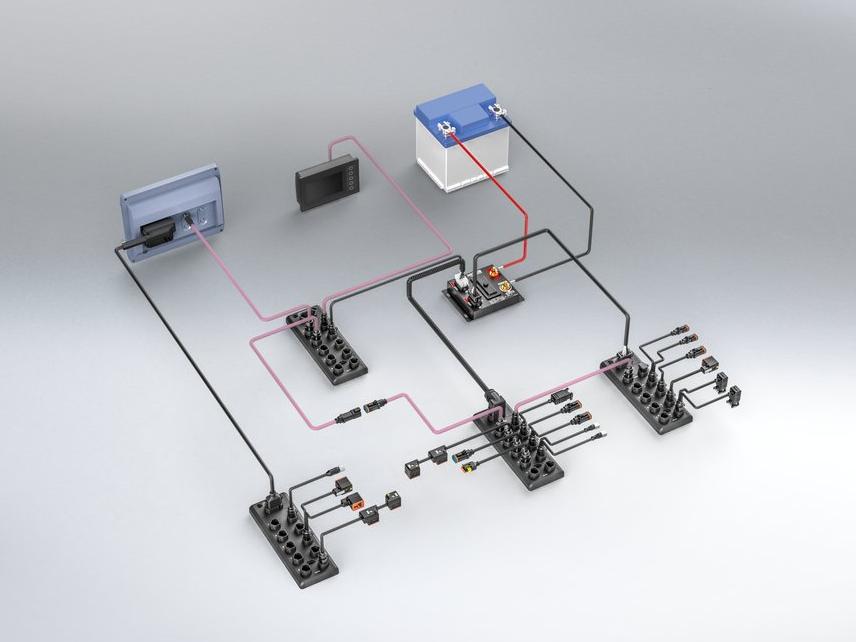

Data Panel GmbH, a company in the Murrelektronik Group, now offers an electronic installation solution for mobile machinery that is said to be modular, highly flexible and future-proof

Mobile machinery is still in its infancy when it comes to what Murrelektronik refers to as "rational installation technology". Although cable harnesses and terminal boxes acurrently remain the dominant technology, in recent years more electronic technologies have found their way into machines and this has had a direct effect on the wiring effort for machine builders. Further, manufacturers also have more options in their product range to better cover market requirements, one result of which is that the traditional cable harness and terminal box solutions are increasingly reaching their limits.

Depending on the type of machine, some manufacturers say that due to the weight, the cable harness can only be installed with several helping hands and in some cases, the support of an indoor crane may be required. Machine builders will be aware that another critical situation is that when connecting many individual strands, it is sometimes difficult to ensure that each individual strand is tightened and leakproof. If even a single seal fails, moisture or an operating medium can penetrate into the housing of the controller, sensor or actuator with the net result that the machine can fail.

Simple, fast and error-free assembly

In March 2020, the Murrelektronik Group founded Data Panel GmbH with the aim of either solving or eliminating the problems and weaknesses just outlined. Its portfolio includes high-quality, decentralised electrotechnical installation solutions for mobile machinery. This modular system (comprising of fieldbus modules, passive distributors and pre-assembled cables) is stated to offer a highly coordinated, modular and pluggable system. Specifically manufactured for the mobile machines market, Murrelektronik claims that the new system has “revolutionised wiring and cabling” and makes it possible to economically work with smaller batch sizes.

The fully encapsulated CANopen fieldbus modules from the company’s xtremeDB product family offer eight slots for inputs or outputs. The signal types (digital, analogue, ratiometric, frequency/counter and encoder signals) can be individually configured for inputs. DO (4A/10A), PWM/PWM(I) and PVG valve controls on the output side round off the signal range.

Thanks to an end-to-end DT-compatible connection technology, the module, which is made of a reinforced plastic housing material, can be used in machines in which the designer can use pre-assembled sheathed cables or, alternatively, use single wires for connection if preferred.

The use of passive distributors creates the intermediate step from parallel wiring harness or terminal box wiring to the plugged fieldbus technology and also offers the possibility of bringing "on-board" inputs and outputs on the controller into the field simply and cost-effectively says Murrelektronik. In contrast to the cable harness, the plug-in system allows subsequent expansions or adaptations of the machine electronics without any problems.

With the complete xtremeDB product family, machine setup and commissioning can be carried out without expert knowledge using Murrelektronik's pre-assembled and tested connection cables based on DT plug-in technology. When these connecting cables are used, the active and passive modules are confirmed to meet IP68, IP66K, and IP69K standards. Alternatively, the cable can be assembled with DT or compatible connectors. The modular system of pre-assembled and tested components and a wide range of accessories ensure a high degree of independence when wiring sensors and actuators. Another advantage of xtremeDB is the independence from cable manufacturers that it provides. Due to the easy handling of the components of the new modular installation system, machine builders are not dependent on their capacity resources.

In the terminal box, the change of technology results in a significant space saving, since additional input and output modules and the potential terminal level are replaced in addition to the mobile control. This means that signals are no longer wired individually and laboriously "in the box", but simply and efficiently installed -decentralised- in the machine. As a result the terminal box can therefore be smaller or possibly, in some cases, even completely omitted. Cable glands (and thus potential weak points) are no longer required. As a result, says Murrelektronik, installation time is reduced to a minimum and when servicing is required, the connecting cables can be quickly and easily replaced on site or repaired with self-attachable plugs.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

5 Albion Street, Pendlebury Industrial Estate

Swinton

M27 4FG

UNITED KINGDOM

+44 (0)161 728 3133