Posted to News on 4th Jan 2022, 08:57

Regenerative energy: underestimated efficiency factor for machines

Many processes, particularly those that occur cyclically, have a high potential of regenerative energy that could be utilised easily and efficiently the operative word being could'

When it comes to the technical solution and implementation of machines, energy is often burned up in braking resistors, which is not only a waste of energy, but also a fire hazard. Supply and regenerative units offer a practical and cost-effective alternative, argues Mark Checkley, managing director of KEB UK.

Many drive applications could benefit from the use of supply and regeneration units, whereby kinetic energy from braking or recirculating can be reused and fed back into the DC circuit through the drive or fed back onto the mains power supply line.

Traditionally, if an application generated excess kinetic energy, it was simply dissipated electrically or mechanically – through a braking resistor or through friction. By utilising regeneration drive systems, this unused, ‘lost’ energy now has valuable potential in many industrial applications by recirculating or feeding back onto the mains supply, reducing electrical running costs, as well as eliminating the heating effects from the braking resistors.

‘Intermediate storage’ and harvesting

The energy can also be put in ‘intermediate storage’ and harvested for use later to cope with any peak energy demands (due to heavy loads or high accelerations) from the application. Generator load cycles also frequently occur with electric drives, where historically the energy was often ‘heated’ in ballast circuits, can now take advantage of this technology.

In order to identify suitable applications for supply and regenerative units, before system integration a check will need to be made whether sufficient regenerative energy will be generated for sensible use. In addition to transporting this energy away, the infeed and regenerative unit also serve as ‘feeders’.

This allows the number of feed points to be reduced and significantly simplifies the planning of the control cabinet. In order to deduce the possible applications, the application itself and its utilisation must be considered. This raises the question of where the regenerative energy is actually being generated. The answer lies in wherever masses are decelerated and therefore if kinetic energy can be converted.

Storage and retrieval machine as application example

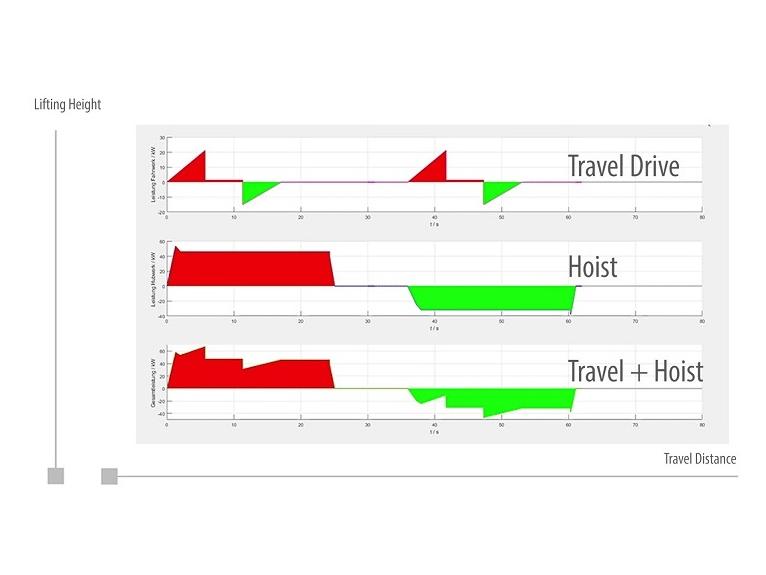

A typical storage and retrieval machine consists of running gear, a hoist unit and a load-handling device. These machines normally have a high mass – the optimal application for a power supply and regen unit. When accelerating such a mass by the running gear, very high power is required. The same applies to the braking process. Here, a drive controller can be used to electrically decelerate the masses quickly and safely. All the regenerative energy generated in this process can be dissipated by a supply and regen unit.

Hoist applications are even greater sources of this energy, which is generated during each ‘lowering’ operation depending on the load being handled. Even when all axes are coupled in a DC link to exchange energy, there is still a significant amount of energy left over.

In other industrial sectors, potential applications for supply and regen units include woodworking, textile machines, process technology, wind turbines and generators, theatre technology, theme parks, centrifuges, cranes, conveyor systems, elevators and test benches. In this context, KEB is often asked whether plant operators are allowed to feed back into the public power grid at all. The answer is ‘yes’ because they are not classed as power generation plants.

Compelling economic choice

Regeneration becomes a compelling economic choice when the value of the recovered energy is large compared to the cost of a regenerative system. So, if the system requires frequent braking and starting, or where there is speed control of overhauling loads, it would be worth considering, provided a clear understanding of the system dynamics are known.

Active or passive feed-in are possible. Passive feed-in means that the infeed and regen unit are grid-connected and the DC link is fixed based on the infeed voltage. On the other hand, active feed-in means that the infeed and regen unit are actively controlled, for example, to regulate the DC link voltage. Both systems offer different advantages:

KEB COMBIVERT R6 supply and regenerative system:

- Suitable for industrial applications with regenerative energy

- Cost effective application

- Compact and lightweight solutions

- Easy to install.

Active infeed converter KEB COMBIVERT AIC:

- Sinusoidal currents to reduce harmonics

- Reactive power reduction for large outputs

- Power factor correction with cos = 1

- Stabilised DC voltage and step-up converter

- Extended speed range and more torque in the field weakening range

- For highly dynamic applications.

In addition to the technical and ecological advantages, a regen unit also brings economic benefits. Often the acquisition costs have paid for themselves after less than two years, after which, you also earn money with the expanded system. The payback period is quickly determined by the utilisation of the system, the number of motion cycles and the price of electricity.

Supply and regen units are an easy replacement solution for braking resistors and they can be used for all common supply voltages of 180...528V AC, 50/60Hz. Most are compact and lightweight, and are often supplied with an integrated pre-charging circuit along with optional choke or harmonic filter.

As braking resistors are no longer required, supply and regeneration units can reduce the risk of heat/fire in sensitive areas, as well as reducing the cooling requirements of the environment. Optional fieldbus interfaces are normally provided, as well as freely configurable inputs and outputs. For some applications, users can even fit energy meters, in order to validate their energy savings.