Posted to News on 12th Aug 2021, 09:05

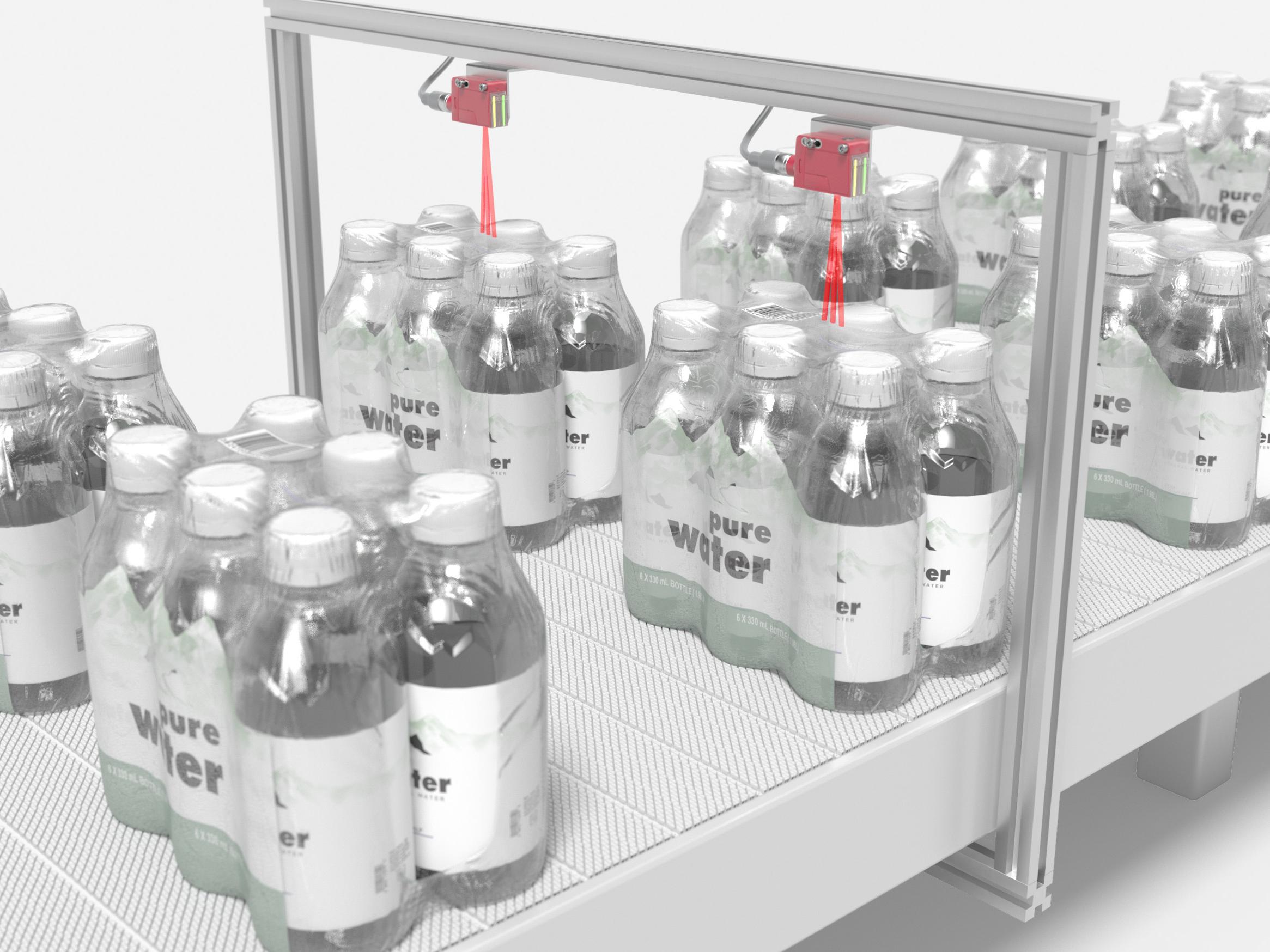

Reliable detection of shrink-wrapped packages

Leuze DRT25C.R dynamic reference diffuse sensor offers simple solution for dependable detection

Leuze is expanding its range of dynamic reference diffuse sensors with the addition of the DRT 25C.R container sensor. “These new sensors are based on innovative CAT technology (Contrast Adaptive Teach), which enables the sensors to reference the conveyor belt and not the object itself,” explains Leuze.

“Multi-packs may be convenient for the transport of beverage bottles or cans, but, when it comes to packaging, the diversity of these multi-packs can be a challenge for plant operators. Foil-wrapped containers can be metallic, colourful or transparent, or there might be holes in the film or cardboard. However, most significantly, beverage containers vary widely in shape and height. These variations make reliable detection challenging.”

Overcoming the challenges

The DRT25C.R dynamic reference diffuse sensor from Leuze overcomes these challenges, says the company, as it is installed above the conveyor belt and uses the conveyor as its reference point. “The flexible sensor detects all objects that differ from the conveyor belt surface. Detection from above is object-independent and reliable. With its high operating range of up to 450 mm, the DRT25C.R detects six-, eight- and multi-packs, regardless of height or whether they are transparent, metallic or have printed film.”

Only one sensor is needed per roller conveyor, regardless of the customer’s specific application. Set-up takes very little time, too. By pressing the teach button once, the conveyor surface is saved as the reference value and additionally two teach levels offer maximum flexibility.

Further time is saved for plant operators when there is a product changeover, as the reference is still the same, meaning there is no requirement to change settings.

“Unlike traditional diffuse reflection sensors, the container sensor remains reliable, if vibrations and contamination occur on the conveyor belt. These are compensated for by the in-built CAT technology. Plant operators who need additional functions, such as warning messages, can easily integrate these via an IO-Link.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500