Posted to News on 11th Dec 2019, 14:23

Renishaw software improves additive manufacturing visualisation

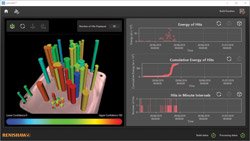

At formnext 2019, Renishaw launched Sonic, a new acoustic process monitoring software to form part of the company's InfiniAM suite. Sonic enables engineers to detect acoustic events within the additive manufacturing (AM) build chamber and turn this data into useful information on build quality. The software is the first of its kind in the AM industry.

The Sonic package includes four acoustic energy sensors to detect vibration in the build, which can be installed into any Renishaw machine. These act like microphones to collect data so that it can be turned into an analysable digital signal. Because each sensor measures the same noise at a different time, due to the speed of sound, the software can triangulate the position of the noise on the build plate using the time difference between when each sensor detected the event. In addition, the software will present a level of certainty about where the noise occurred. Data can be easily viewed in graphical form, to give the user the best understanding of what's taking place.

David Ewing, AM Applications and Software Manager at Renishaw explains: "The rapid heating and cooling that takes place during an AM build leads to residual stress in the part. While each contraction's stress is small, stress can build up with the part and if the it increases past the strength of the metal it can lead to part failure.

"Renishaw's software suite makes it a lot easier to visualise what is happening during an AM build. Renishaw first added InfiniAM Spectral and InfiniAM Central to its range to give manufacturers eyes into their AM, now we've launched Sonic to be the ears. These tools will help engineers to better understand their AM processes and identify defects early on, so that they can stop the build, saving material and time."

Sonic works alongside InfiniAM Central and Spectral, which provide improved understanding of build quality, increased confidence in the build process and accelerated process development. InfiniAM Central is even available on an app, so that users can receive push notifications on their build process and event history in near real-time.

Renishaw is the only UK manufacturer of metal additive manufacturing machines. Its product portfolio includes the RenAM 500Q, a highly-productive machine that includes four lasers in the most commonly used platform size.

Follow the link for further information on Renishaw's software for additive manufacturing.