Posted to News on 9th Dec 2020, 08:58

Replacement linear guides give rise to savings at bakery

By switching to a type of linear system with integrated lubrication a large bakery is said to be saving more than 200,000 a year in maintenance and downtime costs

Previously, on average, the linear guides serving the process-integrated band cutters in the bakery’s dough slicing systems were failing every three weeks, despite being coated with an Armoloy finish and using food-grade grease.To overcome this the bakery sought a linear guide that would offer a longer service life and also be capable of higher speeds given that the company planned to boost the productivity of its dough slicers by 20%.

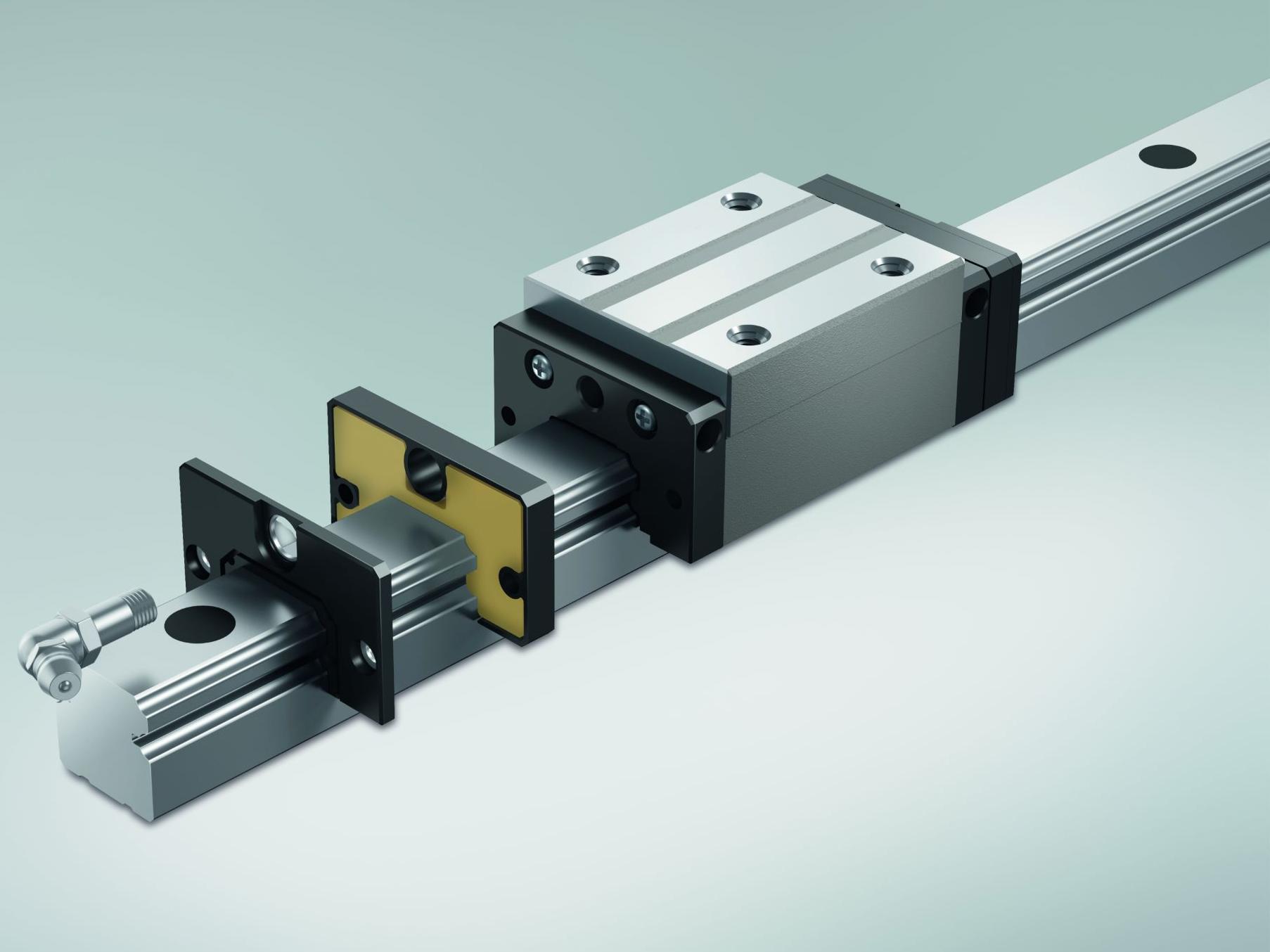

NSK’s AIP (Added Value Programme), staff performed an on-site assessment of the application’s environmental conditions, as well as studying the linear guides that had failed. Once complete, the team recommended the use of NSK NH/NS series stainless steel linear guides in combination with a K1 food-grade lubrication unit. After an initial trial had been completed successfully, it prompted the bakery to fit all of its dough slicing machines with the same equipment.

NSK’s K1 lubrication units are stated to provide a clean and FDA-approved solution in the truest sense of the word because the lubricant is incorporated in a carrier medium and released little by little to ensure supply over a long time period. Meticulous sealing prevents contaminants from reaching the running surface, and far less lubricant is released into the surroundings.According to the bakery, since changing to the NH/NS series, it now performs maintenance routines after 32 weeks at the earliest, rather than replacing the linear guides every three weeks. This is said to represent at least a tenfold increase in service life with annual savings calculated at €206,000 thanks to the need for fewer replacements together with reduced maintenance and machine downtime.

To further extend the potential benefits, NSK has recently introduced its K1-L lubrication unit. The K1-L houses a new polyolefin-based carrier material with a much larger reserve of lubricant, leading to a service life which is typically double that of the K1 series. Fully compatible with NH/NS series linear guides, the K1-L acts as a direct replacement for existing K1 units.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Office 4, Arlington Business Park

Gateway 1000

Whittle Way

SG1 2FP

UNITED KINGDOM

0800 634 1909