Posted to News on 24th Jul 2011, 14:51

Researchers use NI products to develop haptic feedback device

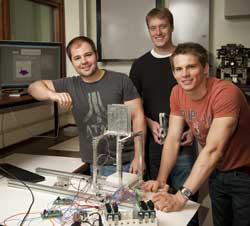

Researchers at the University of Leeds have used National Instruments CompactDAQ hardware and LabVIEW software to develop a haptic feedback device to aid surgeons performing robot-assisted surgery.

Over 10 million people worldwide are diagnosed with cancer each year. More than one in three people will develop some form of cancer in their lifetime and approximately one in four of all deaths are caused by cancer. Typically cancer manifests as hard abnormal masses (tumours) embedded within softer tissue (organs). In the case of malignant tumours, early detection and accurate removal increases the patient's likelihood of survival. Recent years have seen a transfer of surgical procedures from traditional open surgery to Minimally Invasive Surgery (MIS) and, more recently, to robot-assisted laparoscopic surgery. These procedures have shown significant benefits over open surgery, but the lack of direct physical contact has resulted in a loss of haptic (force and touch) feedback, which is required for assessing tissue features through palpation.

At The University of Leeds, UK, researchers have developed a simulation system that delivers haptic feedback to a user during a virtual MIS palpation exercise. Potential applications for the system include surgical training, and further development into a master/slave palpation device. The long-term goal is to overcome the drawbacks of new technology in surgery for the detection and improved resection accuracy of tumours through palpation. To achieve this, the researchers required hardware I/O, third-party hardware interfacing, virtual graphics and custom data handling and processing. Other systems make use of a combination of embedded hardware and a range of programming environments, but the team realised that all of this functionality could be achieved using NI LabVIEW and NI CompactDAQ, delivering inherent compatibility between the various project functions.

System concept

To simulate the palpation of human tissue, LabVIEW was used to create a virtual environment in which the user is presented with a probe and tissue sample within a patient's abdomen. Haptic interaction with the virtual environment is provided through the use of a haptic device. LabVIEW was also used to control a custom-built physical testing environment, where silicon tissue models were palpated with a force-sensing probe. The physical tests were primarily performed to validate the data obtained from the Finite Element Analysis (FEA) but, in addition, establishing communication between the physical testing environment and the haptic device as an opportunity to explore the system's remote palpation capabilities. The response forces that are provided to the user in the LabVIEW virtual environment were determined using FEA.

Physical measurement system

In order to measure response forces from silicone tissue models during palpation, a tri-axial Cartesian robotic system was developed, capable of moving an instrumented palpation probe relative to the tissue models. Using NI LabVIEW and CompactDAQ, the researchers were able to progress from concept to a functioning system in a matter of weeks. The system produces response surfaces of tissue models by recording force measurements during palpation at specified in-plane positions.

The NI CompactDAQ offered a quick and elegant method of sending signals to the motor controllers and enabled position and force measurements to be recorded. The system was programmed to run autonomously using a LabVIEW state machine architecture and allowed parameters such as indentation depth and palpation resolution to be adjusted from the front panel.

Haptic surgical system

In order to simulate the visual and haptic aspects of palpation during surgery, a bespoke Dynamic Link Library (DLL) was created to interface with the haptic device (PHANToM Omni, SensAble Technologies). This allows two-way communication between LabVIEW and the OpenHaptics API to, for example, measure the device end-effector position and to programmatically implement forcing through the device. The 'Call Library Function Node' is used to export and import data to and from the DLL, enabling the set up of the required parameters for the system. This way, the team was able to access the device's functions and build ready-made subVIs to the developer could create flexible haptic scenes quickly and easily, without the need to access the low-level device functions.

Forces are generated by sending predetermined forcing variables to the DLL from LabVIEW. These are then implemented dynamically using a Gaussian function to generate a force in a haptic control loop that operates at a frequency of 1kHz. A stiffness function is then used to adjust the force as a function of the indentation depth. This results in the generation of high-fidelity haptic feedback giving smooth forcing during tissue interaction. LabVIEW's 3D toolbox was used to create the visual scene which includes a deformable tissue surface under manipulation of a robotic probe. A height array is programmatically updated, depending on the position of the end effector to deliver representative visual deformation of the surface. Objects used within the final visualisation make use of virtual reality modelling language (VRML) CAD geometry files to increase the quality of the rendered scene. Coupling the user's sense of touch with visual feedback in this way mimics real-world physical interaction.

To test the final system and assess how well users could detect tumours within the virtual tissues, the researchers carried out a human factors study. This was automated within the code, allowing randomised tissue surfaces to be loaded automatically and other variables to be controlled programmatically, altogether improving the validity of our statistical results. LabVIEW made it easy to implement and customise the trials, allowing robust data handling and post processing.

Advantages of the National Instruments products

The researchers say that NI hardware and LabVIEW gave them solution that met, and exceeded, all the expectations of their project. They state: "In offering an unrivalled functionality and integrating easily with third-party technologies, National Instruments products helped us to meet our project demands with space left for future system development. In addition, National Instruments have an excellent support network, from their dedicated support personnel to the extensive website; it was always possible to get the advice we needed." [The researchers were James Chandler, Matthew Dickson, Earle Jamieson, Thomas Mueller, Thomas Reid, Dr Peter Culmer and Dr Rob Hewson, all from the School of Mechanical Engineering at the University of Leeds, UK.]

For more information about NI hardware and software, go to www.ni.com.

National Instruments Corporation (UK) Ltd

Measurement House, Newbury Business Park

London Road

RG14 2PZ

UNITED KINGDOM

+44 (0)1635 523545