Posted to News on 28th May 2021, 09:15

Robot welding yields efficiency benefits for machine builders

Investment in robotic systems accelerates

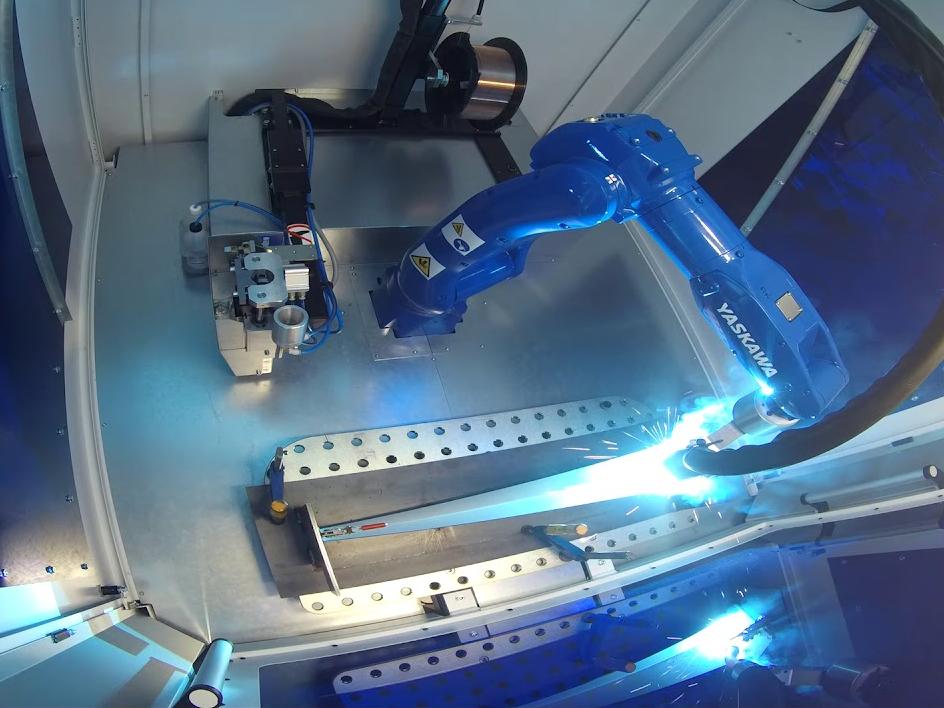

Exploring the benefits of using robotic systems across a wider range of manufacturing applications has accelerated recently where investment in the most up-to-date systems is making a significant contribution to maximising efficiency. Welding applications are a good example and the availability of new, highly flexible, space-saving systems is helping manufacturers to integrate robotics into their welding and fabrication processes.

Less space, more output is not surprisingly high on the ‘wish list’ for any forward-thinking manufacturer and the ArcWorld standard systems available from Yaskawa are said to be ideal for replacing or supplementing manual welding in metal manufacturing applications.

“These fully integrated systems offer the distinct advantage of being self-contained,” adds the company, “so it’s a bit like buying any machine tool – you choose the size of machine you need and a location to install it, and away you go”.

Small footprint

The Yaskawa ArcWorld HS Micro and RS Mini systems are described as easy to install, operate and relocate in a small footprint of either 2.3 sq ms for the Mini or as little as 1.4 sq ms for the Micro. “Both systems offer the possibility for operators to double their output with up to half the preparation time, compared to manual welding,” states Yaskawa. The Micro system is supplied complete with robot and controller and its hinged door opening provides lots of options, even though it’s a very small, compact system. The Mini system has a revolving door and table, which again means maximum flexibility within a compact system.

“The systems are designed to allow quick changes of jigs, which is crucial in helping to reduce the all-important set-up time and improving production output, compared to conventional manual welding practices."

In fine fettling

"Furthermore, improved operational consistency by never missing a weld and ensuring the same quality of weld at the end of the shift as at the start also means reduced ‘spatter’, which improves the capacity for fettling,” says Yaskawa.

Both systems incorporate a MOTOMAN-AR900 robot with YRC1000 controller, a start/stop button panel and fume extraction hood. They also feature a platform and casing with dark green polycarbonate glare shield protection and CE-marking.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>