Posted to News on 14th Jul 2022, 15:30

Robotic sprayer increases consistency and reduces waste

In the eyes of some manufacturers, installing an industrial robot can seem intimidating. Misconceptions of having to rebuild everything from the ground up and having to adopt a completely new process can make automation seem like a bigger endeavour than it truly is.

In reality, there are many ways to embrace automation without starting from scratch, and the available resources make programming and maintaining a robot possible for all knowledge levels – including first-timers.

Baton, a manufacturer of AirStone faux stone veneers and siding, learned this first-hand when it installed its first robot with the help of Dakswan Automation. Once implemented, the Kawasaki RS080N general purpose robot helped Baton cut down production time and significantly reduce waste, with minimal changes made to their existing production line and tooling.

Prior to automation, in order to produce AirStone, four painters sprayed liquid cement onto moulds as they approached on a conveyor. Each painter used a different amount of material, resulting in inconsistent products and over-use of materials. Further, workers were required to wear respirator masks while spraying the moulds to remain safe and minimise exposure to liquid cement particles while on the job.

For manufacturers whose products are constructed in harsh environments, it can be difficult to retain employees, and that task is even more challenging during an industry-wide labour shortage. This lack of consistency can lead to low production, and is a primary reason why Baton decided to automate their spraying process.

Minimal process changes only

The RS080N was Baton’s first robot, so the manufacturer was hesitant due to concerns that this new equipment would be disruptive to the process it had developed over the past five years. Dakswan needed to design a customised solution that aligned with its customer’s manual process

“It took years to develop our spray system that applies colour into our product, and the manual gun we use works well for a number of reasons. It would have been hard to replace,” said Tom Scanlan, owner and president of Baton.

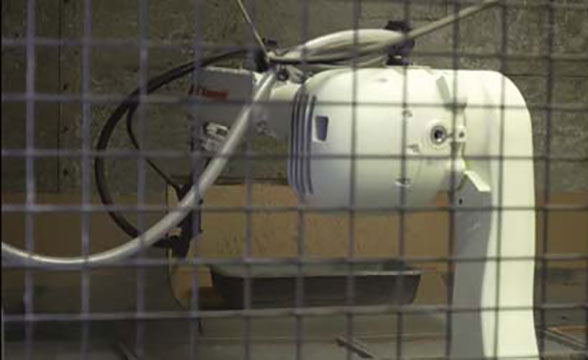

The robot is positioned in the same place as the workers were previously. When the parts arrive in front of the robot on a conveyor, the robot is programmed to paint at the same speed as the human workers before it, but the robot’s ability to work all day without breaks saves average of 2.5 hours of downtime each week.

Choosing a robot from Kawasaki’s line of high-performance, general purpose robots, as opposed to paint robots, was a purposeful choice by the integrator, who picked this specific model due to its long reach capabilities. The RS080N robot’s extended reach (2,100 mm) made it perfect for Baton’s application, which required the robot to spray a large area from one fixed location.

Kawasaki’s R series robots are designed to be effective in workspaces large and small. In addition to their extended reach, the large rotation range of the R series’ axes translates to a larger usable work area with minimal dead space, so multiple robots can be installed in high-density applications without impeding performance. The slim arm design of the R series requires very little floor space, making them a good option for tight spaces, like Baton’s paint booth.

Kawasaki’s option for a built-in PLC, called K-Logic, was another key selling point for Dakswan Automation. K-Logic streamlines operations for the end user because all communication between the production line and the robot is done internally. K-Logic also kept costs down by eliminating the need for an external PLC, and minimising the amount of external cabling needed.

Same process, modernised

Because the RS080N robot isn’t designed for performing paint/spray applications, Dakswan designed a custom end-of-arm tool to hold the exact same paint system their customer was currently using. This allowed Baton to retrofit their current paint gun, utilise spare parts it had acquired over years of using this machine, and keep its end product consistent with what it had sold in the past.

Dakswan installed the robot in the same place the human workers stood during the manual process, which meant Baton could keep its existing machinery and equipment in the same location, and only small adjustments needed to accommodate the new robot.

Although Baton is technically a first-time robot user, the knowledge its maintenance staff acquired from the operations and programming training course they took at Kawasaki’s training centre has enabled them to keep their robot up and running smoothly entirely on their own. Additionally, they are able to reprogram the robot to test out different spraying patterns for new products.

After installing their RS080N robot to perform a ‘human unfriendly’ task, the benefits of automation showed themselves in multiple ways throughout the company. Baton saw a boost in production, so the workers who formerly sprayed the AirStone moulds were redeployed to the different areas of the company that don’t require exposure to harsh chemicals or protective gear.

“Since we hadn’t had any experience with robots, there was apprehension (around) the robot going down, how often that could happen – or if (the robot) was going to cause headaches with our manufacturing process,” said Scanlan. “But it’s been the opposite. It works every day – we don’t really have to do anything.”

From an operational standpoint, Scanlan uses the words “worry-free” to describe using the new Kawasaki robot – despite his initial concerns as a first-time robot user. “It was a very easy process to convert over from manual to robotic. Without a doubt, worth the investment,” he said. “It’s been such an apparent positive to our plant: the reduction of material costs, reduction of downtime — all of it. Using the robot is just kind of worry-free.”

For Baton, automation didn’t mean overhauling a proven process or experiencing stress from complex programming or unexpected shutdowns. The robot has improved Baton’s manufacturing process while creating a safer work environment for its employees. Dakswan Automation designed and implemented a cost-effective solution that utilised the machinery and tooling Baton had spent years adopting, making for a seamless transition and a robotic solution it is able to maintain entirely on its own.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 4, Easter Court

Europa Boulevard, Westbrook

WA5 7ZB

UNITED KINGDOM

+44 (0)1925 713000