Posted to News on 7th Dec 2022, 13:46

Safe radar system brings better protection for robot cells

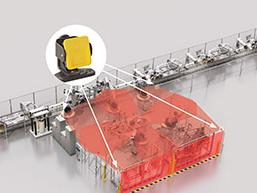

Sick has launched the safeRS3, a next-generation safe 3D radar system designed to enable maximum productivity with highly-reliable safe access protection for workers in hazardous industrial areas, including robot cells.

The robust radar detection principle is ideal for heavy industrial or harsh outdoor environments, which may challenge conventional optical detection systems.

Incorporating best-in-class safe radar technology, the Sick safeRS3 is an electro-sensitive 3D protective device for safe personal detection. With a higher measurement accuracy, it protects personnel in stationary applications to PLd or SIL2 in line with ISO 13849-1 and IEC 62061.

With the safeRS3, Sick has achieved a longer 5m protective field range, with to a 100° opening angle and the ability to set up to four protective fields. A safety-over-networks version has been introduced with Profinet control for easy integration into a PROFIsafe network.

The safeRS3 extends the versatility of safe radar to more industrial applications. As a category 3 device, the safeRS3 can be used in robotic applications in accordance with ISO 10218-2.

With the safeRS3, operators can avoid unnecessary machine downtime while continuing to safeguard personnel. A safe automatic restart function helps to ensure maximum productivity in more complex machine cells, including those with robots. The validation view helps operators to view where field infringements are in real time, so false trips can be identified quickly.

The Sick safeRS3’s 60GHz radar detection principle ensures it can filter out particles or contamination in dirty or high-humidity conditions. The safeRS3 is not affected by low or bright light. It performs accurately despite dirt, dust clouds, woodchips, plastic particles, flying swarf or sparks or steam, heavy rain or humidity.

Safe radar for harsh environments

Operating at temperatures between -40 °C to +60 °C, the Sick safeRS3 offers reliable protection in heavy industrial facilities including steel production, timber or plastics fabrication or in outdoor environments, for example where gantry cranes are operating in bulk materials handling facilities, mines or quarries.

Because of its technology and 3D cone-shaped coverage, Sick says the safeRS3 is ideal for hazardous areas with more complex topography. Steps, platforms, and supports, for example, can cause shadowing effects and could therefore be difficult to cover comprehensively using laser scanners, which detect in 2D planes.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>