Posted to News on 20th Oct 2008, 12:41

Scanning head laser systems gain extended field of view

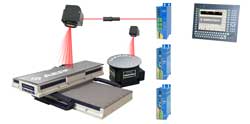

Aerotech's new Nmark SSaM (Synchronised Scanner and Motion) extends the application potential for galvanometer-based laser scanners, with direct control of XY2-100 protocol scan head mirrors in synchronisation with up to 32 distributed and networked servo-driven positioning axes.

Based upon Aerotech's advanced A3200 software-based motion control system, with its fully deterministic FireWire network, the SSaM provides co-ordinated control of the galvo scanning head, the laser functions and servo-driven linear or rotary positioning stages. This effectively extends the scanner's field of view for large work areas by removing the need to stitch or join several exposures together and improves throughput speeds and overall accuracy for high-speed laser marking, cutting, welding, sealing and ablation applications.

In addition, full machine control includes HMI and PLC functions for built-in opto-isolated digital and analogue I/O, as well as specific laser commands for first pulse suppression, first pulse delay and the ability for on-the-fly synchronisation. For raster-type laser scanning for bar codes, bitmaps and scribing, Aerotech's BroadMark feature ensures the entire large area scan is completed in one pass, thereby eliminating angular errors associated with stitching many smaller scans. Similarly, for vector-type laser applications, multiple galvo and mechanical axes are interpolated for continuous laser marking or welding using a 'stretched vector' feature that ensures each process is completed in a single pass of the laser.

Easy interfacing

An industry-standard XY2-100 scanner communication interface supports up to three axes, two galvo mirrors and a third focus axis for dynamic laser focus control. The Nmark SSaM provides an integrated programming environment based upon the RS-274 G-code language that is well supported by major CAD/CAM vendors for direct conversion from CAD data to galvo and scanner motion paths. Additional simple-to-use AeroBASIC command extensions are available for laser and machine I/O functions.

Aerotech's range of high-performance linear and rotary positioning stages includes traditional ball screw and wormwheel mechanics in addition to high-performance direct-drive linear and rotary stages specifically aimed at high-throughput production applications such as laser machining, complete with extensive built-in protection for harsh environments. With backlash-free operation, long working life and sub-micron precision performance, these stages are available for travel ranges exceeding 1.5m and speeds of over 3m/s in stacked stage or gantry configurations. Motion sub-systems can be supplied completely assembled and fully tested with cable management and application-optimised configuration files preloaded into software, thereby reducing commissioning and installation times and further reducing costs.