Posted to News on 19th Sep 2015, 15:05

Schaeffler custom spherical plain bearings for lifting system

Schaeffler has secured its largest ever order for ELGES spherical plain bearings. Schaeffler will supply more than 240 bearings with outside diameters ranging from 400mm to 1060mm, for the Topsides Lift System on the Pioneering Spirit, a purpose-built ship used for the installation and decommissioning of offshore oil platforms.

Built by offshore contractor Allseas, Pioneering Spirit (formerly Pieter Schelte) is the world's largest working ship. As well as installing oil platforms and laying pipelines, the vessel is equipped with a Topsides Lift System (TLS) that has a capacity of up to 48,000 tonnes. This enables the installation of extremely heavy platform topsides, while its Jacket Lift System (JLS) can remove and install steel platform substructures weighing up to 25,000 tonnes each.

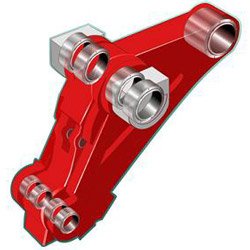

Schaeffler is supplying custom-designed, maintenance-free large spherical plain bearings with an ELGOGLIDE sliding layer to Allseas for the TLS levers, and to Bosch Rexroth for the TLS hydraulic cylinders.

As the ship moves into position alongside an offshore oil platform, which is firmly anchored to the seabed, the movements of the ocean waves cause enormous loads on the ship. The function of the TLS levers is to compensate for these loads. In turn, the TLS hydraulic cylinders ensure that the platform topsides can be elevated and lifted off safely without causing any damage. This means the bearings must provide very high load-carrying capacities in order to compensate for these loads and to allow for movement of the hydraulic cylinders.

Plain bearings are well suited for the low-speed rotary, swiveling and tilting movements, where high loads are also present. For offshore applications, bearings must provide very high corrosion resistance, high moisture resistance for the sliding material, and must be maintenance free over their operating life of at least 25 years.

Certified by Lloyd's Register

Spherical plain bearings in X-life quality from Schaeffler are equipped with very robust, maintenance-free ELGOGLIDE material. The bearings are certified by Lloyd's Register to meet the safety requirements of the marine industry. They also have an optimised screw connection on the axially split outer ring. To improve its adhesive properties and to optimise moisture resistance, the fabric is treated before the hardening process. Overall, X-life optimisation has resulted in 15 per cent higher load ratings for the bearing and a 15 per cent increase in operating life. This also means additional benefits for the customer, including the opportunity to downsize the bearings, as well as longer service intervals and an increase in the overall cost of ownership.

Schaeffler has extended its range of plain bearings to offer a wide variety of maintenance-free plain bearing materials. In addition to the maintenance-free ELGOGLIDE plain bearings, which have proven themselves over many years, the product range now also includes Metal-Polymer Composite plain bearings and plain bearings with ELGOTEX.

Bearings with a dry-running, low-friction ELGOGLIDE sliding layer are suitable for supporting oscillating motion, as their dynamic load ratings are very high relative to their weight. ELGOGLIDE is a sliding layer consisting of a lattice of PTFE and support fibres within a synthetic resin matrix and attached by a high-strength adhesive bond to the steel support body. The result is a balanced combination of high load-carrying capacity, excellent wear and friction behaviour and good dry-running characteristics. The ELGOGLIDE W11 version enables minimal friction at low pressures.

The special properties of Metal-Polymer Composite plain bearings enable low-wear sliding characteristics combined with a high load-carrying capacity and thermal conductivity. The resistance of metal-polymer composite plain bearings has been tested on a wide range of media. An optional design with bronze backing enables the bearings to be used in water. Metal-Polymer Composite plain bearings are a cost effective alternative in applications where minimum space is available and where sliding speeds are relatively high.

Harsh environmental conditions

Bearings subjected to high loads such as those found in construction vehicles, agricultural machinery and conveying equipment, are traditionally equipped with grease or oil-lubricated solid plain bearings. Environmentally friendly and maintenance-free, plain bearings with ELGOTEX are a suitable replacement for these existing products. Due to the combination of materials used, plain bearings with ELGOTEX are maintenance free throughout their operating life and are suitable for use in harsh environmental conditions.

INA plain bearings with ELGOTEX WA, for example, were specially developed for use as rudder bearings and in stabilisers for marine applications. Germanischer Lloyd has certified ELGOTEX WA for loads of up to 15N/mm ² in marine applications. The salt water-resistant ELGOTEX WA material comprises two layers that are wound onto each other. The internal sliding layer, which is embedded in a resin matrix with fillers and solid lubricants, is made of continuous synthetic and PTFE fibres. The external layer also comprises continuous glass fibres in epoxy resin. A specific winding angle stabilises the layers, significantly increasing the strength of the bush.

This combination of materials enables ELGOTEX WA plain bearings to resist corrosive media and allows a constantly low friction value with low wear and zero maintenance. The bearings have a high radial load-carrying capacity, can be used for axial movements, and are insensitive to shocks and edge pressures. Although the bearings are not sealed, if required, they can be supplied with internal seals for additional protection against abrasive contaminants.

For more information about ELGES spherical plain bearings, please visit www.schaeffler.co.uk.