Posted to News on 13th May 2021, 08:59

Schaeffler’s vision: the production of the future

Dr Stefan Spindler, CEO Industrial of Schaeffler AG, has stated that the company wants to occupy a key position in the rapidly growing markets of condition monitoring and robotics. Here is how

Through strategic initiatives and close collaboration, Schaeffler says it offers its customers innovations for the production of the future and that it has set itself an objective: becoming a major partner for lightweight robotics. As smaller robots and cobots are increasingly being used for the automation of handling and assembly tasks, the business has declared its intent to be a key part of these developments.

For several decades Schaeffler has offered a portfolio of products for industrial robotics, based on its conventional bearing range. Expertise from a wide range of business divisions have enabled Schaeffler to make significant leaps into the development of robotics whilst ensuring they remain cost effective with “an outstanding level of quality”.

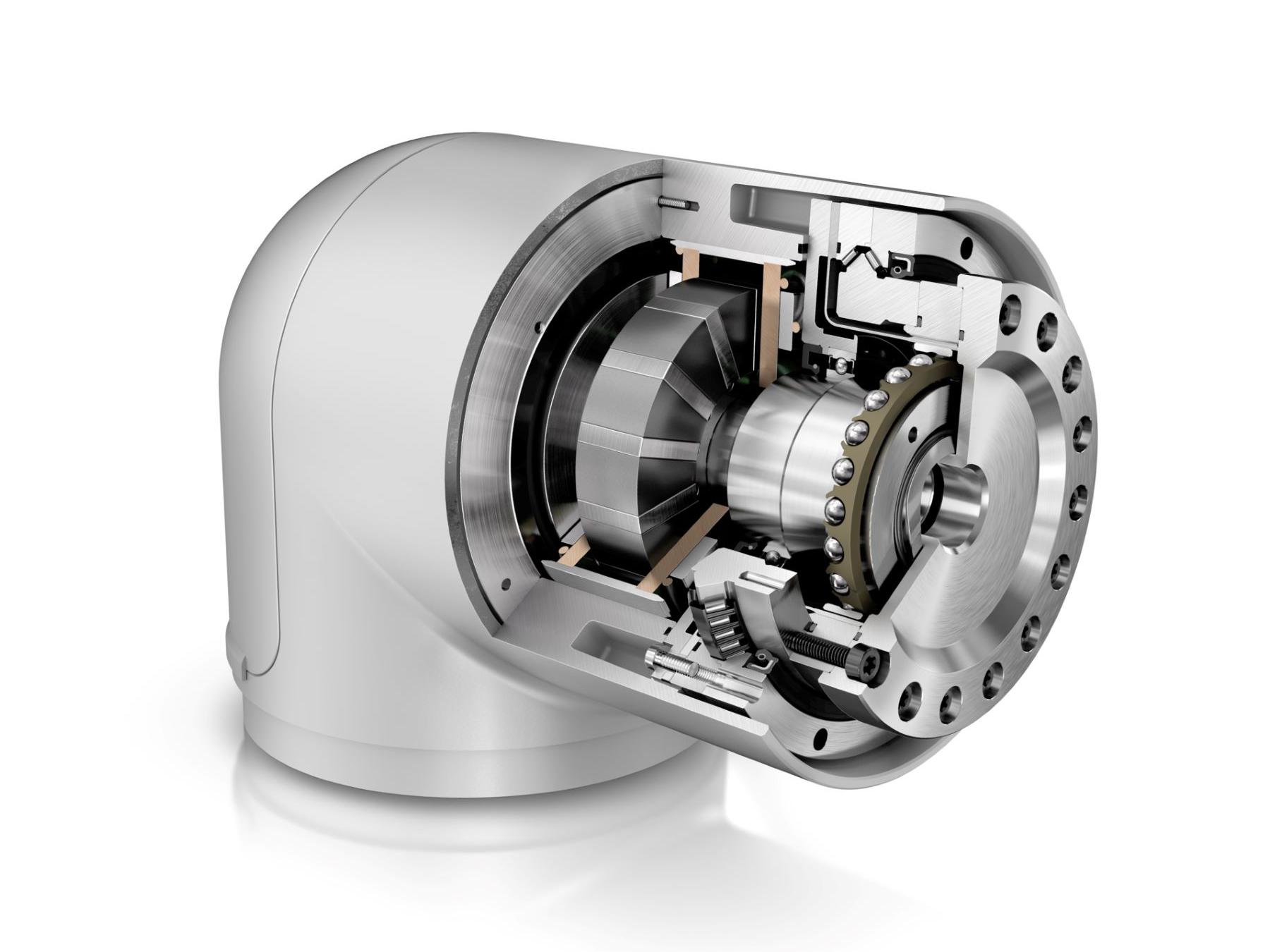

As an example, Schaeffler cites its development of a completely new bearing type specifically for use in articulated arms of lightweight robots and cobots. Other advances in products such as Durawave also demonstrate the ability of the company to evolve in areas of application for lightweight robots and cobots. Further, the company has a modular portfolio of bearing supports, robot gearboxes and drive motors to spearhead its desire to become the partner of choice for lightweight robotics, all playing a crucial part in the performance of compact robots. As power density and precision improve, these components for lightweight robots and cobots can be used in applications requiring higher speeds together with enhanced cleanliness levels, and increased load-bearing capacity.

Schaeffler offers these components either separately or as matched systems to meet specific customers’ requirements for maximum compactness, dynamics and performance.MachineBuilding.net readers can discover more here.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>