Posted to News on 3rd Feb 2009, 09:42

See innovative linear guides, actuators and lubricators

At this year's Machine Building, Drives & Automation exhibition at the NEC (25-26 March 2009), Schaeffler (stand 808) is showcasing a number of innovative linear motion products, including linear actuators, miniature linear guidance sets and a lubricant metering valve, described as unique, that cuts lubricant consumption by up to 25 per cent on linear guides.

Customers of industrial automation systems and production machinery are now demanding smaller, more compact linear systems from suppliers, combined with increased performance. This also includes systems that are destined for ISO Class 1 clean-room environments, where linear components need to operate in a contaminant-free vacuum. Machine builders are therefore required to source machine components that meet these types of performance specification.

On stand 808, Schaeffler will reveal its new range of miniature linear guidance sets, which offers a number of technical advantages to machine builders, including high performance, high rigidity and compactness.

Miniature guidance sets with cylindrical roller flat cages, for example, are now available. These ready-to-mount units are designed for use as linear locating bearings. The guides are available in numerous guideway lengths, offering very cost-effective designs. A special corrosion-resistant version is also available. The guidance systems are suitable for applications with short stroke lengths, low-friction motion, oscillating movements, high loads (where high rigidity is also required) and for very high accuracy requirements.

High capacity

Schaeffler's RWS1808 miniature linear guidance sets have two rows of rolling elements that provide in-line contact with the raceways. This line contact means the units offer very high load-carrying capacity and rigidity.

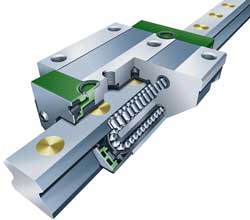

Visitors to the Schaeffler stand will also have an opportunity to see a new range of linear recirculating roller bearings and guidance systems, which can now be fitted with lubricant metering valves. These provide precise doses of lubricant to the linear guides, enabling lubricant consumption to be reduced by as much as 25 per cent compared with standard designs. This leads to a reduction in maintenance and servicing costs and helps customers to preserve resources.

Schaeffler's RUE-E range of roller monorail guidance systems can now be fitted with the SMDS integrated metering valve option, replacing standard O-ring seals. The valves prevent the lubricant duct from running dry, avoid inadequate lubrication or over metering, and enable precise relubrication with very small, precise quantities. The linear guides have only one valve per side and function irrespective of mounting position.

Linear actuators

Also on Schaeffler's stand will be the company's new range of modular linear actuator units for use in both single- and multi-axis compact linear actuator systems. The MKUVS32-KGT linear actuator is a very compact unit with ball screw drive, suitable for a wide range of applications, particularly when secure, rapid, precise and repeatable positioning and movement of light-to-moderate loads is required.

This unit consists of a support rail, one or two carriages (depending on requirements) and a high-precision ball screw drive. The unit enables travel speeds up to 1m/s and accelerations of up to 30m/s2 to be achieved. The drive system is a high-precision ball screw drive (maximum spindle speed is 3000rpm) and users can specify pitches of 2, 4, 10 or 20mm.

Using various accessories such as motor adapter plates and couplings, customers can adapt the actuators to fit their preferred choice of motor. The actuators can also be configured for plug-and-play installation for immediate use.

Schaeffler also offers a full range of accessories for linear actuators, including fasteners, connectors and mounting brackets. These enable faster, easier mounting of actuators on multi-axis handling systems for production processes, machining, handling, assembly, inspection tasks and packaging equipment. Twelve basic mounting brackets are available in various dimensions and fixing arrangements. There are 44 different brackets to choose from.

For location of the linear actuator's support rail, a range of components is available, including profiled aluminium fixing brackets, fixing lugs, T-bolts, T-nuts, hexagonal nuts and T-strips.

Experts will be on hand throughout the exhibition to provide advice and guidance on Schaeffler's comprehensive range of products and services. For more information, please visit www.schaeffler.co.uk or telephone the marketing department on +44 (0)121 351 3833.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>