Posted to News on 5th Nov 2020, 09:31

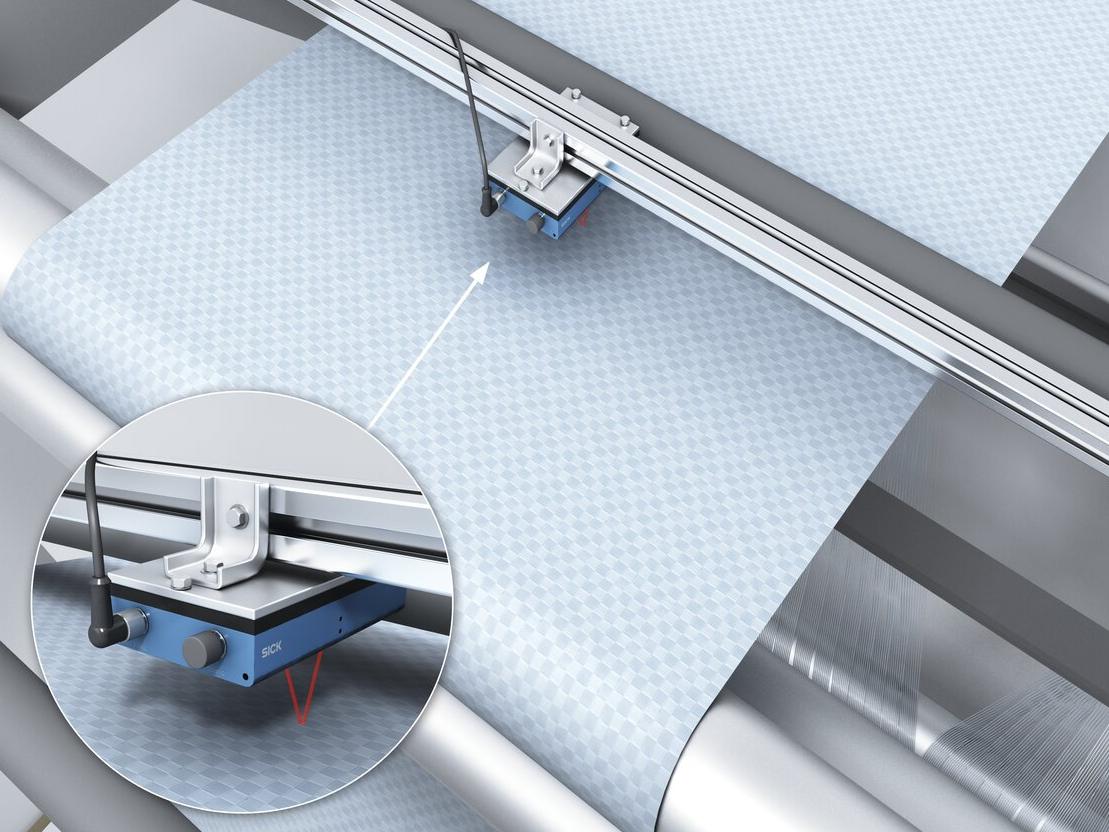

Sensing speed and length on production machinery

With the addition of its new SPEETEC non-contact sensor for speed and length measurement, SICK says it has added a compact, affordable, eye-safe laser surface motion sensor to its portfolio, able to measure a wide range of continuous, web-fed or cut-to-length materials down to a resolution of 4 m

The new sensor is said to provide precision surface measurement in process control and quality inspection tasks, typically on machinery designed for industries such as printing, textiles, tyre manufacture or building materials production. The Class 1 eye-safe infra-red laser eliminates the need for special guarding or safety measures required by some conventional velocimeters.

SPEETEC® uses the Laser Doppler principle to work at speeds between 0.1m/s and 10m/s to measure directly on the material surface with an accuracy of 0.1%, and a repeatability of 0.05%. According to SICK, typical return on investment can be achieved in under 12 months and the new sensor offers higher levels of measurement and throughput speeds than previous options.

SICK’s Darren Pratt observes “The SPEETEC®’s non-contact measurement principle means it can be used where a measuring wheel in contact with the substrate would never have produced completely reliable results. There’s no danger of damage to the material, which is important, especially for delicate, smooth or soft materials such as extrusions or textiles. Nor is there any need for marks or scales on the material itself. What’s more, unlike a measuring wheel which can wear over time due to abrasion with the material surface, the SPEETEC®’s non-contact measurement function cannot be impaired in this way, so maintenance and downtime is reduced.”

Product testing and field trials have shown SPEETEC® to be reliable even when measuring materials with challenging, highly reflective, dark-black or uneven surfaces says SICK. The company also expects machine builders and operators to turn to the new sensor to increase process speeds in applications where rotary encoders or measuring wheels might be prone to inaccuracy due to slippage of the material.

The new SPEETEC® sensor is said to be easy to mount due to its generous mounting tolerances and compact design. The aluminium housing measures just 140mm x 95mm x 32.5mm and the sensor can be set up in a matter of minutes without any supplementary electronics to process the signal output. The Laser Doppler measurement is automatically converted on board the sensor into TTL/HTL signals identical to those of an incremental encoder, so that they can be easily integrated into the machine control system.