Posted to News on 22nd Mar 2018, 13:01

Sensor data available globally: beyond the local company cloud

Making sensor data and information from different sources available globally and linking this data and information in a meaningful way - this is the crux of Industry 4.0. New business ideas make it necessary to make this information globally available and accessible not only within a company but also beyond the boundaries of the company and its location.

Sensors are the eyes and ears of automation technology and provide a wide variety of information concerning the current condition of a machine or system; for example, about position, pressure and temperature, etc. The diverseness of the information reflects the huge number of sources used. Ultimately, however, the focus in the case of Industry 4.0 is: how is it possible to access this data and information from different sources, to link it in a meaningful way, to aggregate it and to make it available globally? On the one hand, there is information that is generated at field or control level. On the other hand, there is information that needs to be managed centrally, e.g. in MES or ERP systems. The main issue here is that the information to be linked must not only be available and accessible within a company or location, but must frequently also be exchanged beyond location boundaries in order to acquire new information.

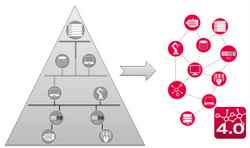

Data in the classic automation pyramid flows from one level to the next: sensors or actuators at the field level communicate with the higher level control only; the machine control exchanges its data with Production Planning which in turn exchanges data with the company's ERP. These system transitions present an obstacle as they usually filter data. To overcome and functionally develop these obstacles is usually very time-consuming and costly - in practice this is achieved using gateways or protocol converters. The elimination of this obstacle must therefore be the primary objective of all Industry 4.0 activities.

Private clouds

In the majority of all production processes, it will not be possible to fully overcome these obstacles because production processes are performed at a high cycle rate or precisely defined sequences have to be observed. Options for deterministic communication between participants at field level through to ERP systems in an open architecture are currently being developed. Furthermore, a central pool which can be addressed directly from different sources is formed parallel to the existing transfer processes. For this purpose, many companies set up a "private cloud" or "edge cloud" on an internal server or a private tenant in the cloud on which the access permissions are kept completely "privat" at first.

If, as part of new business ideas and models, it becomes necessary to make individual items of information available to other companies, locations or clouds, this information can be exchanged between different tenants, taking specific usage authorisations into consideration. The cloud capacities are scalable and allow large quantities of data to be recorded - even data for which it is not currently clear whether and which knowledge can be derived from it, or whether it can be used at a later time to generate benefits or even business cases.

The primary objective is therefore to first record data from a wide variety of different sources, to aggregate this data and to make it available. The next step is to link the data. It will only later become clear whether this data can potentially be used for new business models. Metaphorically speaking, we are currently constructing a highway on which goods can be transported at a later stage and to which we can then attach business cases. At the moment no one knows exactly where this highway will lead.

In the past, point-to-point connections between the control unit and the respective sensor or actuator have dominated industrial automation. A master-slave communication model is currently dominant. This means that a control unit usually serves multiple end devices via one cable in linear topology (fieldbus installation). The use of new technologies will allow a transition to a netlike or star-shaped communication architecture, which we already know from the IT sector. By connecting the automation network (OT) and IT network of a company, it will be possible to exchange data between all levels and in all directions. To link and, in particular, evaluate this data, it is essential that it is current or is given a dedicated time reference and has a specific, for example, geographical, reference.

Data availability

Leuze electronic initially actively tackled the subject of data availability and has for the first time transferred data directly, across all system boundaries, from the sensor to the cloud. For this purpose, Leuze electronic integrated an OPC UA server in its sensor and docked onto the Microsoft Azure Cloud with the publisher-subscriber model. Whereas OPC UA communication is currently based on a client-server architecture in which the recipient determines the data volume and the frequency of data exchange, the publish-subscribe method is preferred for communication with cloud applications because here, although the recipient (subscriber) selects the data to be transferred, it is the producer (publisher) that is responsible for distributing the data at the necessary or, from an application perspective, appropriate points in time - similar to a newsletter. Leuze electronic has extended this transition by the IoT Proxy from Microsoft to enable data transfer universally in all directions. The proxy now makes it possible to analogically operate client-server communication to local shop floor concepts. This opens up various migration paths to new, cloud-based applications.

The difference to the classic approaches is that the IIoT concepts rely on globally available data. Therefore, the data can also be networked globally across systems and company borders for interpretation and evaluation purposes. This global data availability immediately raises the question of data integrity. It is an inevitably accepted prerequisite that data integrity must be ensured on communication channels and in globally available systems. OPC UA is tested in line with the federal institute for security and information technology and offers all four generally stipulated safety features for secure communication: authentication, authorisation, verification and encryption. In this way, tested methods and procedures from the world of information technology (IT) are transferred into the world of automation technology (OT - Operations Technology). This can be subsumed under the expression "IT goes OT". Future authentication will take place using certificates. In the future, sensors from Leuze electronic will therefore be equipped with a unique safety certificate in addition to the identification data to date such as their serial number.

To consistently structure the availability of information, detection and addressing of data sources has to be made possible across all system borders from the cloud. This does not entail making unprotected access possible but rather simplifies the installation. It is not practicable to manually publicise a large number of edge devices (e.g. sensors and actuators) to a global cloud system, or to register them in the cloud system. Instead technological mechanisms are required, which make it possible for the cloud system to autonomously identify edge devices that are centrally assigned to it. These mechanisms are called global discovery functionalities. There are two different mechanisms, which are integral parts of the OPC UA standard: local discovery mechanisms (Local Discovery Server) on the one hand, and on the other hand global discovery mechanisms (Global Directory Server). Both of them require an extensive certificate exchange (Trust List Type) to safeguard access. Sensors from Leuze electronic are - corresponding to its client promise "Smarter Usability" - available with secure access in all forms of the discovery mechanisms.

Holistic information provision

One of the core points of Industry 4.0 is the holistic information provision in the life cycle of an asset. In this system approach the ideas of augmented reality technology fit in seamlessly. This technology enriches the actual visible environment with virtual information in the user's field of vision visually on mobile devices such as tablets with stereo camera or data glasses. A decisive advantage is the visualisation of the features and characteristics, which were to date only available in graphics in manuals and web portals. Now they are visibly on display in the field of vision at the appropriate point in the actual space. This simplifies commissioning considerably.

Here, the supplementary virtual information is not just limited to passive data. Taking the example of its code readers, which are typically mounted at a conveyor belt and have to read the bar codes on a passing package, Leuze electronic has demonstrated that the optical (normally invisible) measurement field of the sensor can be displayed during the ongoing process. And that's not all: by connecting to the cloud, the reading result - OK, NOK, code content - can be visualised in the data glasses immediately after each reading operation so that the commissioning engineer or the service employee can check the system's condition online.

The use of new technologies is not just limited to complex devices such as code readers or positioning sensors. Simple triggering photoelectric sensors are also being increasingly integrated in future predictive maintenance concepts in order to safeguard machine and system availability. A first step was made with additional warning messages, for example, when a sensor becomes soiled. This was soon accompanied by a range of configuration options for the sensors via a simple interface. In this context, IO-Link has now become crucial because this simple 3-wire interface offers all the functions needed for new IIoT concepts but can still be integrated at low cost even in very small devices. Particularly worthy of mention here is the dual-channel variant with one channel for the binary switching signals for process mode with a high level of time determinism (i.e. real time), and a second channel for access to identification and parameter data and messages from the sensors.

As the interfaces to the control systems are increasingly Ethernet-based and therefore powerful enough to serve two data channels simultaneously, this is opening up completely new possibilities - and it is exactly these possibilities that are needed for the networked world of Industry 4.0 in order to transfer data to different destinations and levels. Leuze electronic has been following this trend for a long time and decided early on to integrate direct fieldbus access in its complex ident devices and measuring sensors. With two data channels the basis for this is available - through Dual-Channel IO-Link in the case of less complex sensors, and through the integrated fieldbus interface with addition TCP/IP channel in the integrated connectivity devices identified by the red i in their type designation.

To learn more please go to www.leuze.com.

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500