Posted to News on 5th Jul 2022, 13:23

Sick launches real-time energy monitoring of compressed air

As manufacturers face rising energy bills, Sick has launched the FTMg with Monitoring App, an Industry 4.0 solution that helps companies see the data they need to reduce energy consumption through better control of compressed air.

The Sick FTMg with Monitoring App enables production and maintenance teams to monitor compressed air continuously so they can reduce leaks, improve operating efficiency, and cut costs.

Compressed air is the ‘fourth utility’ of manufacturing. According to the British Compressed Air Society, it accounts for 10% of energy use in a typical operation and rises to 30% in heavy use industries.

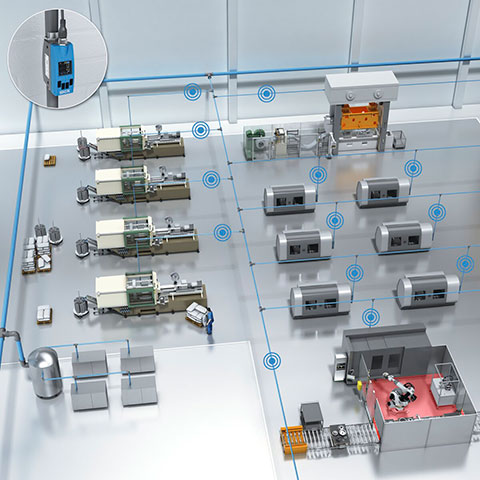

Using data from strategically-positioned Sick FTMg flow meters, the cloud-based FTMg Monitoring App visualises a wealth of both real-time and historic data about compressed air usage. It enables continuous energy management, condition monitoring and predictive maintenance of compressed air systems from any internet-enabled device.

Targeted energy reduction

The FTMg with Monitoring App is a scalable system that can target the compressed air energy use of individual machine cells through to entire production or logistics halls. With no programming needed, it can quickly start visualising continuous compressed air data in a way that is easy to use and interpret. As well as enabling more sustainable use of resources, the data insights support better operational efficiency and help achieve reduced carbon targets, contribute towards ISO50001 Energy Management certification or compliance with the UK Government’s Energy Saving Opportunity Scheme (ESOS).

Darren Pratt, Sick’s UK product manager for industrial instrumentation explains:

“Compressed air is one of the biggest consumers of energy in manufacturing and logistics, and costs are skyrocketing. Many production teams are currently restricted to conducting periodic spot checks, and all too-often, not enough is known about where leaks are, or which machines are the biggest consumers.

“We are already seeing how early adopters of the FTMg Monitoring App are gaining remarkable, and sometimes unexpected, insights. They have been able, for example, to make start-up and shutdown management of processes and machines more efficient, improve compressor control and manage peak loads.”