Posted to News on 16th May 2022, 10:21

Simplified gripper configuration and integration processes

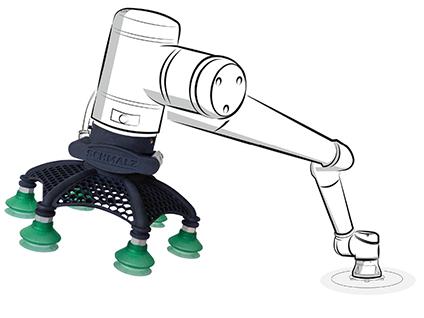

The task of configuring bespoke vacuum gripper systems, which will meet the specific requirements of individual applications has never been easier, thanks to the comprehensive Digital Configuration Services now offered by industry leader Schmalz.

This range of digital services help end users, machine builders and system integrators alike to quickly configure products such as Schmalz SLG Lightweight Gripping Systems for individual applications. Tools such as filters, configurators, ordering aids and apps simplify the process – regardless of the stage of the project, whether it’s product design, procurement, or operation.

A simple and highly intuitive six stage process guides users through steps such as selecting the workpiece, defining the application, selecting the type, number, size, and positions of vacuum cups, and finally choosing a vacuum generator and robot mounting flange. The proposed SLG Lightweight Gripper is then automatically generated, and shown in 3D, on the basis of your input and responses to this series of intuitive choices for the workpiece and the application.

At the end of the process a summary of all of the information used to specify the gripper, together with valuable information for the end user or machine builder covering gripper dimensions, weights, air flow and gripping force etc. is available for download. At this stage, this uniquely specified gripper can be ordered by completing the final steps covering company and contact information.

Additional digital services available from Schmalz make it possible to simulate your handling process with a digital twin of the products you have selected, and test the function of your system, long before it is actually built. For example, it is even possible to obtain information about the behaviour of a suction pad in its operational state. There are also a series of software and function modules, that can be used to integrate Schmalz products even more quickly into the end user’s process and control system. Schmalz tools provide support in device management and parameter setting, getting the product into operation as quickly as possible. Once up and running, open interfaces in Schmalz Connect Suite make device information accessible, and dashboards visualise performance and possible faults.

The ease with which Schmalz have made it possible to specify, configure and order bespoke SLG Lightweight Gripping Systems, plus the availability of digital twin information and functional software modules brings a new dimension to the way we think about gripping technology.

Unit 2 Woodrow Business Centre

4 Woodrow Way

M44 6NN

UNITED KINGDOM

+44 (0) 161 243 4642