Posted to News on 20th Oct 2023, 14:59

Smart sensors provide a built-in diagnostic solution for cylinders

Contrinex’s inductive smart sensors provide hydraulic and pneumatic cylinder and valve manufacturers with an opportunity to add smart-monitoring options to their products as well as enhance their performance.

The smart inductive systems combine robustness, reliability and performance with smart functionality. In this application, they are used to enable a cylinder to optimally accelerate and decelerate to reduce its cycle times without compromising safety or performance. They also provide monitoring capabilities that identify deviations from the norm, providing preventative maintenance information and thus helping ensure a cost-effective, unobtrusive, fit-and-forget solution.

The extra functionality provided by Contrinex’s smart sensors can be utilised in many ways, for example, the cumulative count of detections could be used in a pay-per-use or a warranty verification system.

In addition to detecting the presence of the cylinder at the end of its stroke, an analogue measurement from an inclined face on the cylinder’s push-rod can be used to precisely measure the piston’s position. Therefore, it’s operation can be verified and analysis of variations in position, velocity and acceleration used to warn of the need for maintenance.

The smart sensor can also monitor temperature, providing an over-temperature warning, for example.

Contrinex has a well-established reputation for robustness and reliability and so in this application, it is a significant benefit that the smart sensors share these features and like Contrinex’s conventional high-pressure-rated inductive sensors can operate at 500 Bar with peak pressures of 1,000 Bar.

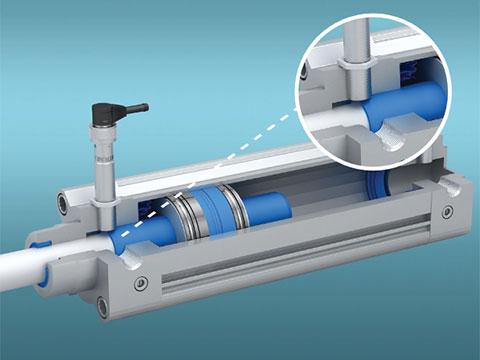

Contrinex smart inductive sensors are embedded into the side wall of a pneumatic cylinder. The sensors are high-precision digital distance-measurement smart sensors, also known by the acronym ‘DMS’. The sensors precisely measure the distance to a longitudinally inclined face at the end of the circumference of the cylinder’s drawbar. At the end of the cylinder’s travel, as the drawbar moves forward, the distance to the slope of the inclined faces changes in direct proportion to the position of the drawbar.

The sensor can measure a distance of up to 6mm to the inclined face with a dynamic resolution of ±5.5 micrometres, delivered in a highly accurate 16-bit digital output to the PLC. This is used to determine the cylinder drawbar’s precise lateral position in real time.

A velocity gradient profile for the cylinder at the end or start of travel can be created using the sensor’s onboard cumulative data store. The PLC can also initially calibrate the two extremes of the cylinder’s travel and record these in the sensor’s local data store. The sensors can then monitor the drawbar in real-time to ensure that it does not exceed the defined extreme of travel and that any non-compliant velocities, acceleration, deceleration or positioning are sent as an alarm to the PLC.

The sensor’s dual-channel capability is utilised to provide secondary monitoring of the cylinder’s temperature. If an over-temperature event is detected, a high-speed serial input/output (SIO) alarm is sent to the PLC, calling for action before there is a risk of wear or damage.

The small and compact size of the sensors makes them ideal for fitting into cylinders, valves or manifolds. Their proven technology, exceptional resistance to extreme vibration during operation as well as best-in-class long-sensing distances ensure highly reliable fit-and-forget operation with no manual intervention.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>