Posted to News on 16th Aug 2022, 11:00

Smoother machinery operation with new spring sleeves

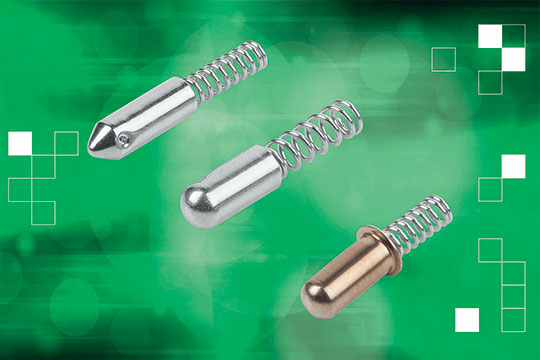

German standard components manufacturer Norelem has introduced a new range of spring sleeves for use as indexing and positioning elements.

Typically, operating elements with latching adjustment points are subject to high loads in daily use. In these instances, using spring sleeves ensures a smoother operation. Norelem’s three-product range of spring sleeves facilitates repetitive positioning operations on machines and equipment or machines and parts that are undergoing machining.

With a spring sleeve, a deep-drawn metal sleeve is connected to a compression spring. The spring is captively connected to the sleeve via a grain. They are used wherever resting and switching processes with a pleasant haptic and acoustic feedback are to be implemented in small spaces. For example, program selector switches on machines, rotary switches, temperature controllers, and household appliances, such as washing machines, dishwashers, or ovens.

“We are proud to introduce our new range of spring sleeves,” says Marcus Schneck, CEO of Norelem. “With this new range, we are able to facilitate repetitive positioning operations for manufacturing in a range of situations. The range, although small, is made to fit in with many different pieces of equipment and ensures a smoother operation across the board. The spring sleeves are manufactured with precision for high-quality applications. Through their use we realise the possibilities of micro assemblies for limited package situations.”

Norelem says that through an innovative manufacturing process, the spring sleeves achieve a consistent quality in the spring forces and geometry of the sleeve. This enables the spring sleeves to be guided precisely into the required component. In fact, a simple borehole is sufficient to accommodate the spring sleeve. The spring sleeve is preloaded and secured by the locking piece on the opposite side.

The sleeves are made of nickel-plated steel and stainless steel, meaning they have excellent corrosion resistance and can resist general wear and tear. The compression spring is always made of stainless steel. There are three springs available in the range aptly named Form A, Form B, and Form C – with small variations in shape being the only differentiating factor. Form A consists of a simple rounded head, Form B has a pointed end, and Form C has a rounded end with a lip at its base.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>