Posted to News on 21st Nov 2010, 21:07

Software simulates loads on wind turbine powertrains

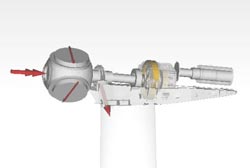

A collaboration between four companies has led to the development of new simulation software that is able to calculate the dynamic operating loads acting on wind turbine powertrains. Used in combination with Finite Element Analysis (FEA) tools, the new complex, multi-body simulation (MBS) model enables designers to optimise the design of individual powertrain components and establish how these interact with other systems across the entire powertrain. The simulation tool, which can be used at the initial wind turbine design stage, will help to make wind turbine designs more reliable and cost effective under a wide variety of load conditions.

The four partners involved in the joint project are rolling bearing manufacturer The Schaeffler Group, gearbox supplier Eickhoff Antriebstechnik GmbH, wind turbine maker Repower Systems AG, and software company Samtech Iberica.

Simulating dynamic operating loads is a critical factor in the design of wind turbines. Despite new wind turbine designs, which have stemmed from new alternative main bearings and gearbox design concepts, as well as greater demands in terms of performance and reliability of turbines, up to now load simulations have been conducted using relatively simple design calculation models.

These simplified models consider only the effects of load over time for specific internal stress variables, independently rather than for all powertrain components and how they interact. This means that complex units, such as gearboxes, which have multiple dynamic components, are treated as a 'black box' and the design of the gearbox and how it affects other parts of the powertrain is not taken into account by this over-simplified model - which could result in an unreliable wind turbine design.

Complex model

To gain a better understanding of the dynamic loads acting on the mechanical powertrain components in a wind turbine, the four project partners have brought together their respective mechanical engineering and software expertise to develop a complex MBS model.

One of the core software applications behind the new MBS model is Bearinx, a rolling bearing calculation software tool developed by the Schaeffler Group. This software is able to generate dynamic simulation models for complete gearboxes, and the results can then be visualised.

Bearinx enables users to make bearing calculations, including shaft deflections and stress calculations of complex bearing and gearbox arrangements. The software helps users to optimise their designs by showing the effect of any changes rapidly. Various bearing designs and shaft deflections can be considered, and then the results can be compared with those from FEA.

Bearing arrangements can be analysed in detail, from single bearings via complex shaft or linear guidance systems, to entire gearboxes and powertrains. The software can model complete gear systems and can simulate the different gearshift conditions of a mechanical or automatic gearbox.

Bearinx takes virtually everything into consideration, including: non-linear elastic deflection behaviour of bearings; the elasticity of shafts and axles; and the influence of fit, temperature and speed on bearing operating clearance, preload and contact angle. The software also takes into account load-related contact angle shifts. Even for complex gears, the contact pressure on each rolling element is considered in the calculation. Lubrication conditions, contamination and actual contact pressure on fatigue life are also taken into account.

Used in combination with dynamic simulations and FEA calculations for adjacent components and housings, Bearinx enables powertrain simulations to be modelled accurately and reliably.

The MBS model that has been developed facilitates integrated calculations of fatigue loads or extreme load conditions that may arise during wind turbine operation, including emergency shutdowns or power failures. Just as important is the fact that having a simulation tool available at an early stage in the design process adds to the confidence in the development process. Development costs are significantly reduced, as any design modifications can be made much earlier in the design process.

For more information, call Schaeffler UK's Marketing Department on +44 (0)121 313 5870 or email [email protected].

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>