Posted to News on 25th May 2022, 10:04

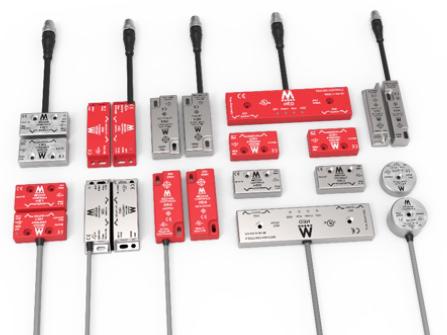

Solid state, coded magnetic, shock proof safety switches

Magnetic reed safety switches definitely have a place in your factory, but certain applications do not present the right conditions for them to survive long periods.

This often leads to them needing to be replaced frequently, resulting in higher long-term costs and increases in production downtime. It is easy to blame the safety switch and its manufacturer for its unreliability without looking at the core reasons for why they fail.

Maybe your failures are due to the plastic fixings breaking or perhaps the position of the guard results in high impact/shock loading when closing the guard. These types of failures are annoying but can be resolved simply and, more importantly, cost effectively.

Mechan Controls’ patented HE-Series switches benefit from three features that most commonly used magnetic reed switches do not offer. The HE-Series uses a coded magnetic switch and actuator that cannot be defeated or tampered with by one, two or even three magnets. Unless the user knows the exact combination of magnetic strengths and polarities, the switch cannot be operated. Most reed safety switches offer no or limited coding and therefore can often be defeated using a standard magnet(s).

The solid-state design means Mechan HE-Series safety switches are shock- and vibration-proof. Standard magnetic safety switches are often mounted on machine lids or perimeter guarding, resulting in high impacts when the guards are being accessed. Operators frequently open and close guards quickly to minimise the machine’s downtime but neglect the damage it causes to the safety switches in the process.

It is also common in high-vibration applications for vibrations to cause the reeds to ‘chatter’, tripping the safety relay/control circuit in the process. The HE-Series switches eliminate this completely, providing the vibrations do not result in the actuator moving out of operating distance from the switch.

Simultaneous switching

Reed switches with more than one contact often suffer from high hysteresis. If there are two normally-closed (N/C) contacts, one N/C contact will change over sooner than the other. This is often seen in applications where gate sagging has changed the angle in which the actuator approaches the safety switch. Most magnetic reed switches have an inherent delay between the two separate safety contacts due to the construction/position of the reeds. Safety relays can detect this delay due to the time limit set between the safety input channels. This can cause interruptions to the output of the machine, consequently reducing productivity.

HE-Series switches use solid-state outputs that do not suffer from hysteresis. This means when the actuator is within operating distance to the switch, all contacts change over at the exact same time. The process is instantaneous and works well with modern safety circuits that are often more sensitive.

Mechan says it is easy to swap magnetic switches to HE-Series switches. HE-Series switches are available in all the common housings and mounting/fixing holes. The contacts use volt-free outputs meaning they will replace traditional magnetic switches without the need to change the existing safety control circuit.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

14/16 Seddon Place

Stanley Industrial Estate

WN8 8EB

UNITED KINGDOM

+44 (0)1695 722264