Posted to News on 14th Oct 2015, 18:11

Solidworks Model Based Definition (MBD) cuts out 2D drawings

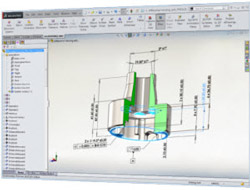

Dassault Systemes is launching Solidworks Model Based Definition (MBD), which it describes as a powerful drawingless manufacturing application. Solidworks MBD provides engineers with a 3D tool for model-based design that improves technical communication, accelerates design and manufacturing processes, and saves production time and costs.

As the use of 3D in today's industrial design and manufacturing processes becomes more prevalent, traditional 2D engineering drawings are proving to be time-consuming, error-prone and non-compliant with industry standards. These inefficiencies waste valuable time, money and resources.

With the Solidworks MBD application, engineers can now generate one master document for all product and manufacturing information, downstream processes, and compliance with regulations and standards, all without having to produce and maintain separate sets of expensive 2D engineering drawings.

Gian Paolo Bassi, the CEO of Solidworks at Dassault Systemes, comments: "Model-based definition methodologies have been shown to reduce manufacturing errors and avoid the expense and time associated with developing 2D drawings, which can run up to 50 per cent of total development costs. Every new Solidworks application that we develop is a reflection of the user community's needs. We have tailored Solidworks MBD to offer patent-pending engineering innovation for easier product design and manufacturing, and faster time-to-market."

Rich Eckenrode, Co-Chairman of the MIL-STD-31000 manufacturing sub-committee, who defined the model-based definition requirements for the United States government procurement officers, adds: "Solidworks MBD's compliance to MIL-STD-31000 Appendix B is close to 100 per cent, if not at 100 per cent. Solidworks MBD's ability to achieve a highly compliant MBD model viewing schema is as good as or even better than other CAD systems."

Solidworks MBD enables more streamlined technical communication using industry-standard file formats. Engineers can define, organise and publish product and manufacturing information directly in 3D to improve communication between design and manufacturing teams and reduce the risk of errors. Solidworks MBD serves multiple use cases including communicating part and assembly information required by manufacturing, request for quotes by purchasing, and inspection reports for the QA department - in each case providing streamlined and more accurate information to all stakeholders.

Solidworks MBD is a key addition to Solidworks 2015 product portfolio unveiled in September 2014. Solidworks 2015 covers all aspects of the product development process with an intuitive, integrated 3D development environment that includes 3D design, simulation, electrical design, product data management and technical communication. With the new Collaborative Sharing feature, Solidworks 2015 enables access to Dassault Systemes' 3DExperience platform and its cloud-based capabilities.

Follow the link for more detailed information about Solidworks MBD.