Posted to News on 12th Dec 2022, 09:55

Speedy set up times with new pneumatic clamping elements

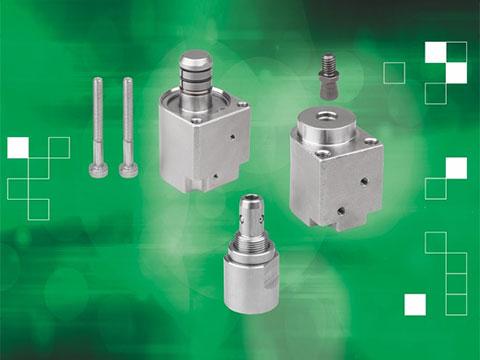

A new range of pneumatic clamping elements from German standard components manufacturer Norelem are designed to speed up set up times by clamping and centring of workpieces.

These new additions to Norelem’s extensive range of over 70,000 standard components are designed for clamping and positioning tasks and are particularly well suited for automatically and quickly exchanging workpieces, such as pallets and fixture plates. Additionally, the clamps allow for the simultaneous (un)clamping of attachments, too, whilst the centring clamp allows for direct positioning and clamping of components, without the need for a counterpart surface.

The pneumatic clamping elements features compact designs and stainless-steel base bodies, with the pin and bush being additionally hardened, which, in addition with the clamp’s rubber seals, prevent wear during frequent cycles. This makes the clamps suitable for use in demanding operating conditions that require strict hygiene standards, such as semiconductor production, food processing, as well as pharmaceutical and cosmetic production.

“We are extremely pleased to be adding these pneumatic clamping elements to our range of products”, says Marcus Schneck, CEO of Norelem. “By using our new pneumatic clamping elements, many industries will benefit from a reduced set up time as well as hygienic clamps that are suitable for even the most demanding conditions.”

The range also includes pneumatic swing and lever clamps, which are used where low clamping forces are sufficient or when the clamping point must be free for inserting and removing the workpiece. Pneumatic swing clamps with a block body are available with either a clockwise or anti-clockwise rotation. Furthermore, swing clamps are available with stroke lengths of 10 or 20 mm for smaller versions and 20 or 50 mm for larger versions. With a maximum operating pressure of 6 bar, the swing clamps can achieve a clamping force of 1.15 kN.

Pneumatic lever clamps can be used to clamp workpieces with a low profile. Compared to swing clamps, an equally sized lever clamp can generate greater clamping forces due to the lever mechanism. With a maximum operating pressure of 7 bar, the lever clamps can achieve a clamping force of up to 1.35 kN.

Screw-in versions of both swing and lever clamps are available too. All screw-in clamps have an adjustable thread length, which means they are suitable for recessed installation within the fixture. The screw in swing clamps having a maximum operating pressure of 6 bar, at which they can achieve a clamping force of up to 1.72 kN. Alternatively, screw-in lever clamps have a maximum operating pressure of seven bar, at which they achieve a clamping force of 1.35 kN.

The screw-in clamps with a fitted flange can be fastened using a slotted nut or four cap screws, whereas screw-in clamps without a flange can be fastened with an external threaded flange or by using a groove nut.

Pneumatic clamping bolts can be used with single-acting and double-acting positioning fixtures. Single acting clamps retract via a spring and the positioning cylinder is then released by compressed air. Whereas, double acting clamps use compressed air both to retract and extend. Our locating adapter, cylindrical works with a single- acting positioning fixtures and guaranteeing a clamping force of 30N. The locating adapter with flange works with a double-acting and guaranteeing a clamping force of 40N.

Completing this range of products, are the centring clamps for direct workpiece clamping, which have clamping diameters between 16-20 mm and a holding force of 77 N (at 0.5 MPa).

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>