Posted to News on 30th Mar 2010, 13:11

Spiral welding machine for equipment refurbishment

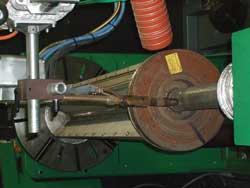

Rewinds and J Windsor Ltd (RJW) has invested around 100,000 in a unique, purpose-built spiral welding machine for the reclamation and refurbishment of rotating equipment and other components for chemical and paper processing, quarrying, marine and general industry.

The investment in the new spiral welder came about through the realisation that existing equipment was too small for the very large components that were being offered and that new equipment on the market was not wholly suitable. Engineering Manager Mark Lavelle therefore decided to design a spiral welder and have it manufactured to his drawings.

According to RJW, the welder offers fully automated control of the weld head position and rotating mechanism to give high accuracy and repeatability. The ability to weld dissimilar metals including high-grade steels ensures that the finished shaft or component has performance characteristics that are equal or better than those of the original. Furthermore, abrasion- and corrosion-resistant materials can be overlaid onto the existing shaft material to improve the performance of the component and significantly extending its useful life. Maximum capacity for shafts is a 1600mm diameter and maximum length is 6000mm.

Benefits of spiral welding

Spiral welding equalises the stresses built up during normal welding processes. Where necessary, pre-heating and post-weld heat treatments are carried out in accordance with the appropriate British Standards.

All drive shaft keyway slots can be repaired and new keyways can be cut. Threaded areas can be reclaimed and recut successfully, and tapered areas can be repaired.

In addition to welding the external diameters of shafts and rollers, the new machine can also refurbish internal bores of wheels and other similar equipment to a minimum diameter of 25mm.

Full material inspection is carried out prior to welding, thereby ensuring that components are free from cracks or flaws. Magnetic particle detection equipment and other non-destructive testing techniques are used throughout the process.

Speaking at the machine's official launch, Dr Robert John, Director of TWI (The Welding Institute), said: "I have been very impressed with my visit today, and seeing a UK engineering company facing the future with such a positive attitude is a pleasure. Not only are you investing in state-of-the-art equipment but you have a thriving apprentice scheme to ensure you have the people to take the company forward."

Contact the company for more information about the new spiral welding machine and its capabilities for refurbishing equipment and components.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

RJW Ltd (Rewinds & J Windsor & Sons (Engineers) Ltd)

81 Regent Road

L5 9SY

UNITED KINGDOM

+44 (0)151 207 2074