Posted to News on 26th Jul 2022, 14:47

Stainless steel increases durability of anti-vibration mounts

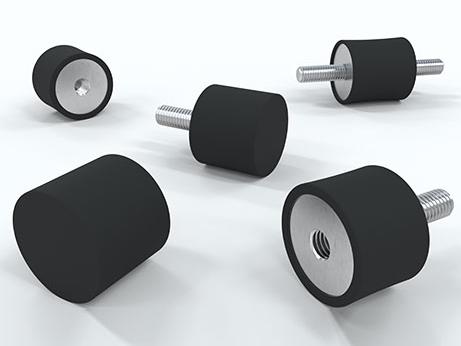

A range of anti-vibration mounts used to reduce noise and increase performance across a range of machinery types is now available in stainless steel is new from WDS Components.

The new design reduces the potential of corrosion and increases durability for OEMs and end users operating with harsh environments or requiring longer lifespan. The anti-vibration mounts are easily installed or retrofitted to applications up to 190.5kg maximum compressive load.

WDS’ range of anti-vibration mounts can be added to any vibrating equipment, such as a machine, motor, or generator, to absorb vibration. This can significantly reduce noise for machine operators or those in the environment. As the mounts reduce vibration of the entire machine, this can improve machine lifetime, decreasing the rate of ware and lowering maintenance requirements. Machine efficiency and performance can also increase as a result.

The anti-vibration mounts comprise a rubber cylinder and can be installed to a machine with either a threaded shaft or a female threaded insert. For installation flexibility, a rubber headed option can be used as a stop for perpendicular installation, or a design capped with a stainless steel disc at either end can be used for parallel mounting.

The new stainless steel range has been developed for OEM demand, increasing durability in corrosion-prone environments, such as those involving chemicals or washdown. The new range also provides longer-life for OEMs or end users looking for improved ware resistance. The range joins WDS’ existing offer of steel anti-vibration mounts.

The rubber cylinder has been selected for optimum vibration absorption, with a hardness rating of 55 Shore A, specially selected for the application range. The mounts can be used for smaller machines with maximum compressive loads from under 4kg and a deflection of 0.9mm, up to heavy loads over 190kg with a deflection of 3.2mm. The smallest mounts have a cylinder length of just 8mm, while the largest extend to 30mm.

Richardshaw Road

Grangefield Ind Estate

LS28 6LE

UNITED KINGDOM

0113 290 9852