Posted to News on 16th Jun 2025, 13:30

Still isolating your entire process for short duration operator tasks?

Whether it's realigning packaging material, clearing minor faults, or adjusting sensors, EUCHNER's CKS2 smart key system enables controlled, traceable access that supports safer and faster operator interventions - helping manufacturers maintain safety without sacrificing productivity. CKS2 is ideal for robotic cells, packaging lines and high-throughput machinery where downtime is costly.

(See EUCHNER at MachineBuilding.Live, 15 October 2025, on stand 224)

Traditional Lockout/Tagout (LOTO) systems have long been the standard approach for ensuring safe access during machine interventions. However, when applied to short-duration, routine tasks - such as material alignment or setup adjustments - LOTO procedures can become unnecessarily time-consuming and, in some cases, lead to non-compliance due to practical pressures on operators.

This is where the EUCHNER CKS2 RFID key system offers a more tailored, efficient solution - maintaining high safety integrity (up to PL e / Cat. 4) while supporting the needs of modern production environments.

Supporting operator interventions with smarter safety

Imagine a situation where an operator needs to realign a misfed stack of packaging material. The task itself may take only a few seconds - but performing it safely using traditional LOTO often requires isolating the entire system at the main control panel, fetching and attaching a padlock, and completing several procedural steps. In fast-paced environments, this can introduce friction, increase downtime, and, critically, create conditions where safety steps may be skipped.

With CKS2, the safety system becomes part of the operator's workflow - not a barrier to it.

How the CKS2 system works

The CKS2 key is normally held within a key reader mounted adjacent to the access point. When the key is present, the machine is in production mode. To gain access, the operator removes the key - this triggers a safe shutdown of the relevant zone or process.

The key remains with the operator while inside the cell, preventing any restart until it is safely returned to the reader. Importantly, the system can be configured to allow partial process shutdown, enabling lower- risk areas of the machine to continue operating where appropriate.

This approach significantly reduces the time burden of traditional isolation while ensuring that access remains controlled, traceable, and compliant with relevant standards.

Additional safety measures for complex installations

Zoned access control: Specific areas can be shut down without halting the entire system

Internal key readers: Additional readers can be installed inside large cells, requiring a physical 'safety sweep' before restart - ideal for safeguarding operators who may remain inside the area

Multiple keys with colour coding: Where multiple personnel may enter, colour-coded keys stored at the point of entry help track who is inside. The system can prevent restart until all keys are returned, enhancing team safety

Traceability: Every key usage event can be logged

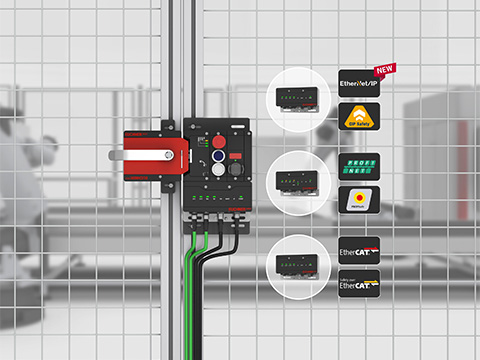

Flexible integration: The system can be networked via IO-Link, PROFINET, EtherCAT, and more

Designed for real-world production challenges

The robust design and modular structure of the CKS2 make it suitable for a wide range of industrial applications, from packaging lines and robotic cells to complex processing equipment. Its ability to combine practical safety enforcement with operator usability ensures that safety systems are followed - not bypassed.

Whether used for short operator interventions, routine setup tasks, or machine adjustment, the CKS2 provides a clear, repeatable process that maintains compliance and helps to reduce the risk of human error.

Looking beyond the padlock

Traditional LOTO certainly has its place - particularly for maintenance and more complex longer-term interventions. But for frequent, short-duration access, CKS2 offers a smarter, more effective approach that keeps both safety and efficiency in balance.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>